Few names in the history of boat design inspire the awe of the Rybovitch legend. The first boat to have all the design features of a modern sportfisherman was a 1952 Rybovitch named

Miss Chevy II. She had no trunk cabin, a raised deck forward with a reverse sheer, a true flying bridge, aluminum outriggers, a tuna tower, low freeboard aft, and a transom door for landing big fish. She’d look right at home in a 21st century boat show.

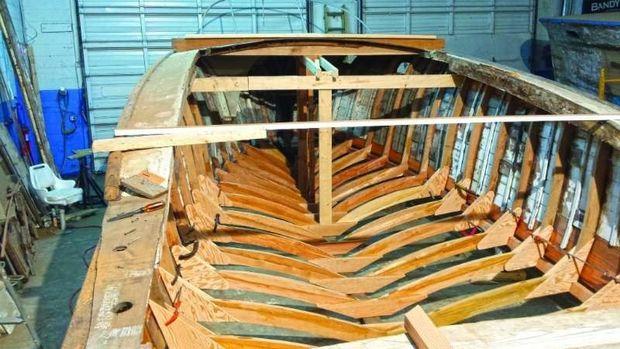

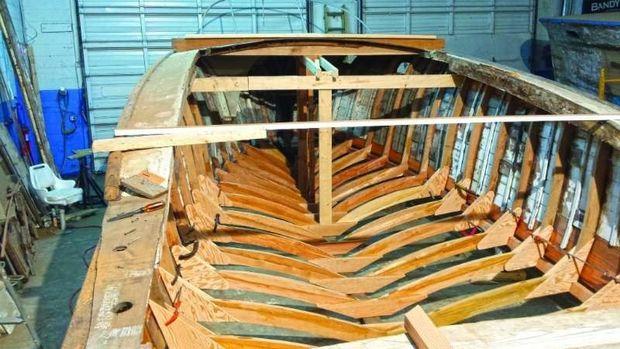

Reid Bandy of Bandy Boats in Riva, MD, has undertaken a modern revival of these legendary boats. “A good friend Mark Hall and I purchased two old Rybovich boats to restore. We have rented space at Casa Rio Marina in Mayo, MD, and have been working hard since October. Both boats have a colorful history, and mine was in particularly bad shape. I have stripped and re-framed mine. They are day boats, 36 feet in length, designed in the early 50s for tuna and sail fishing. Mark’s boat is hull number 12 built in 1954, and mine is hull number 18 built in 1955.

“Both boats are major restorations. They were edge-glued mahogany topsides on sawn-oak frames. They were fastened with anchorfast ring-shank monel nails, set and bunged. We redesigned the bottoms for modern power packages with common rail diesels and also evolved single-engine pocketed drive lines. We have utilized cold-molded techniques to recreate the hull bottoms. We are coating everything with epoxy. We took lines off both boats and are digitizing jigs to reconstruct the houses, decks, and fly bridge with core cell foam. If we can keep the weights limited to 15,000 pounds, we will have impressive performance.

“Our new propeller pockets will allow a shaft angle of less than four degrees. I don’t know of any diesel inboard powerboat (without pods) with such a shallow shaft angle. We are hoping for cruise speeds in the 27-knot range and therefore have attempted to stiffen the hulls by 40 percent to accept the higher bottom loads. John Bildahl has shot over 1000 images so far, and we are very happy having him document our progress every day. We should finish exterior hull lamination within two weeks and roll the boats over to begin drive line installation shortly thereafter. We are hoping to achieve a unique blend of classic style, low maintenance and outstanding performance.”

Jake Glover of Ferry Point Marina in Trappe, MD, has stayed busy this winter. “We have a custom 32-foot bay boat in for a number of updates. She will receive a new Garmin electronics package, Lewmar windlass, and Jabsco sanitation system just to name a few. We also have a couple of new AwlGrip paint jobs to knock out before spring as well as a number of Interlux InterProtect and Bottom Paint systems to have ready for launch. Our north bulkhead replacement is complete! We will have an open house on April 2.”

Rob Hardy of Composite Yacht in Trappe, MD, has also had a busy winter. “We’ve been lucky to have a wide range of projects to keep us busy here at Composite Yacht. We’ve done several repowers, as well as numerous fabrication projects ranging from wind tunnel parts to a large hardtop and cabin extension on a DeFever 49. Our paint department stays busy year round, and we have several builds underway, on both our Chesapeake Bay and Offshore platforms. We’re also plugging away (pun intended) on the plug for the all new Offshore 32, which we’re very excited about. We hope to have a completed hull mold within the next month or so.”

Smoky Glover of Willard Marine in Virginia Beach, VA

Smoky Glover of Willard Marine in Virginia Beach, VA, reports in. “The SeaArk Commander Fire and Rescue boat belonging to the Avenue MD Volunteer Fire and Rescue Department is currently undergoing repower, repaint, structural, mechanical and electrical repair and upgrades to the firefighting system at the Willard Marine facility in Virginia Beach VA. New Yamaha outboards will be installed, along with a new fire pump and monitor… Willard Marine now owns rights to the SeaArk Marine line of commercial and government boats.”

Patrick Callahan at Worton Creek Marina in Chestertown, MD

Patrick Callahan at Worton Creek Marina in Chestertown, MD, sends us this update: “At Worton Creek we have fabricated and installed a custom hardtop on the aft deck of a 47-foot trawler. The aluminum railing is being extended around the top deck to include the hardtop. When complete, the hard top will have a freshly applied non-skid surface on top and new overhead lighting below. We also have several other fabrication and paint jobs going on.”

We are pleased to welcome a new contributor,

Forrester Boatworks of Suffolk, VA, this month. “My name is Carson Forrester, and I am a small boat builder. I am currently building a small 17-foot skiff. I have two mate boats to build after this one is completed.”

Jonathon Newton of Hartge Yacht Yard in Galesville, MD, reports on a busy winter. “The mild weather of late fall and early winter really helped us get a good start to our busy winter. The buy boat

Muriel Eileen is back together and in the water. New and old pieces in the shaft log area were re-secured with custom-made bronze bolts to replace the wasted away iron drifts and bolts. Not wanting large washers and nuts protruding from the bottom, some bolts were welded to plates that neatly fit to the deadrise and buttocks lines. The interior, aft of the engine and around the stuffing box, is mostly reassembled and being painted. Before long we will be starting on the sampson posts and chunk stern—a term for round sterns built from chunks of wood stacked like bricks and drift pinned together.”

On the other side of Galesville,

Nancy Bray Booth of Hartge Yacht Harbor is also staying busy. “From bow to stern, Hartge Yacht Harbor is preparing to paint a 51-foot Dettling motor yacht inside the paint building. This yacht will take extensive sanding and preparation and will eventually have a new Awlgrip Stars n’ Stripes blue hull with off-white decks and cabin. By the time this winter is over, she will be looking good and ready for cruising. This boat is one of several Awlgrip paint jobs that we will be doing this winter and spring. We just completed an Awlgrip hull paint job in Flag Blue on a Swan 44.”

From Denton MD, Meg Roney of Mathews Brothers Boatworks

From Denton MD, Meg Roney of Mathews Brothers Boatworks has had a busy winter as well. “Spring is almost here! It’s been a cold winter, but we’ve kept warm this winter by working on several major jobs in addition to the minor repairs on our storage boats so they are ready to go when boating season arrives. We have a Wilbur 34 in the shop with the engine pulled out while we replace the fuel tanks and clean up the bilge. Our varnish crew finished up a complete strip and rebuild varnish job on a Hinckley 36 and is working through maintenance coats on the rest of our storage boats.

“The guys are in the process of prepping another boat for paint after moving the Hinckley out of the paint booth. Some of the minor repairs we’ve done include replacing windshield gasket and hinges, fixing a cracked bowsprit, replacing a faulty float switch, and replacing control cables. The pilothouse on the buy boat

Crow Bros II is coming along—the tongue and groove overhead is almost complete. We’re in the middle of glassing the cabin walls and will start the V planking shortly. Down at the landing, the insides of the buy boat hull have been painted, and the steering system is well under way.”

Lauren Distefano of Bluewater Yacht Yards in Hampton, VA

Lauren Distefano of Bluewater Yacht Yards in Hampton, VA, reports. “One of our big projects we are working on is

Sea Toy, a 59-foot Spencer yacht. She’s arguably one of the East Coast’s most popular and well known charter boats run by Captain Bull Tollson. Her complete engine re-power requires disassembly of the interior, removing couches, carpet, and salon door and removal of salon floor hatches; and removal of reverse gears from engines and engine accessories as needed for clearance. Then we reassemble engines, install new engine controls and displays, align engines, run new harnesses, and make all connections. Sea trials and reassembly of the interior to original condition will complete the job. A Sea Keeper installation as well as an all over paint job will put the final touches on the job.”

Tracey Johns of the Chesapeake Bay Maritime Museum in St. Michaels, MD

Tracey Johns of the Chesapeake Bay Maritime Museum in St. Michaels, MD, sends us this report for the month. “Chesapeake Bay Maritime Museum’s Jenn Kuhn reports

Pin Tail, a 25-foot Hooper Island Draketail, is now under construction in the boat shop. Built by CBMM’s Apprentice for a Day (AFAD) public boat building program participants, the build will continue through this spring, with the hull completed in June with the engine install and launch anticipated for late August. The boat features a reverse-rake round stern which is also referred to locally as a “torpedo stern,” “dovetail,” or “ducktail.” These were the first types of power workboats developed in the Chesapeake Bay region, having their heyday in the ‘20s and going out of style in the ‘40s when crab-potting became legal.

“The

Pin Tail is being built using plank-on-frame and started upside down on a strong-back. The bottom will be traditionally cross-planked with bead and cove strip planking for the topsides. White oak is being used for the keel, stem, chines, rails, and bed logs. Atlantic white cedar is being used for planking, with locust used for the knees and breast hook. The finished boat will be available for purchase, with proceeds supporting the boat restoration projects of the museum. The public can join in on the build throughout the process for one or more AFAD sessions, which take place on weekends through June. CBMM is offering a reduced $25 participation fee the third Saturday of each month. For more information or to register, email Jenn Kuhn at

[email protected].”

Tammy Eaton of Judge Yachts in Denton, MD, winds up our month with a newsy and enthusiastic report: “Wow—what don’t we have going on this month? The crew continues to work on the several 36s and 27s we have going as well as preparing for our Open House on February 20. Along with all the other beautiful boats featured at our Open House, from our center consoles to the Chesapeakes, will be the Chesapeake 36 with Twins and the 36 with Triple Suzukis. Getting all of those boats prepared and staged so as to allow our attendees the chance to climb aboard and explore them takes a little finesse and finagling, but they always get it done. Finally for those clients that have their boats in storage with us, we are working on upgrades, additions, and maintenance. Gotta get those Judges ready for Spring!”

We are pleased to welcome another new contributor this month.

Chad Brenner from Classic Restoration & Supply in Vintage Craft Boats in Philadelphia, PA, sends us this report. “We are currently working on a bunch of projects, some to include a 25 foot Chris Craft Sea Skiff in for a new paint job, along with some mechanicals and underwater hardware replacement. Alongside the Chris Craft we have a 1985 Donzi. We just re-gelcoated the whole boat, wet sanded and buffed and we are getting ready for delivery.”

by Capt. Rick Franke

by Capt. Rick Franke “Both boats are major restorations. They were edge-glued mahogany topsides on sawn-oak frames. They were fastened with anchorfast ring-shank monel nails, set and bunged. We redesigned the bottoms for modern power packages with common rail diesels and also evolved single-engine pocketed drive lines. We have utilized cold-molded techniques to recreate the hull bottoms. We are coating everything with epoxy. We took lines off both boats and are digitizing jigs to reconstruct the houses, decks, and fly bridge with core cell foam. If we can keep the weights limited to 15,000 pounds, we will have impressive performance.

“Our new propeller pockets will allow a shaft angle of less than four degrees. I don’t know of any diesel inboard powerboat (without pods) with such a shallow shaft angle. We are hoping for cruise speeds in the 27-knot range and therefore have attempted to stiffen the hulls by 40 percent to accept the higher bottom loads. John Bildahl has shot over 1000 images so far, and we are very happy having him document our progress every day. We should finish exterior hull lamination within two weeks and roll the boats over to begin drive line installation shortly thereafter. We are hoping to achieve a unique blend of classic style, low maintenance and outstanding performance.”

Jake Glover of Ferry Point Marina in Trappe, MD, has stayed busy this winter. “We have a custom 32-foot bay boat in for a number of updates. She will receive a new Garmin electronics package, Lewmar windlass, and Jabsco sanitation system just to name a few. We also have a couple of new AwlGrip paint jobs to knock out before spring as well as a number of Interlux InterProtect and Bottom Paint systems to have ready for launch. Our north bulkhead replacement is complete! We will have an open house on April 2.”

Rob Hardy of Composite Yacht in Trappe, MD, has also had a busy winter. “We’ve been lucky to have a wide range of projects to keep us busy here at Composite Yacht. We’ve done several repowers, as well as numerous fabrication projects ranging from wind tunnel parts to a large hardtop and cabin extension on a DeFever 49. Our paint department stays busy year round, and we have several builds underway, on both our Chesapeake Bay and Offshore platforms. We’re also plugging away (pun intended) on the plug for the all new Offshore 32, which we’re very excited about. We hope to have a completed hull mold within the next month or so.”

“Both boats are major restorations. They were edge-glued mahogany topsides on sawn-oak frames. They were fastened with anchorfast ring-shank monel nails, set and bunged. We redesigned the bottoms for modern power packages with common rail diesels and also evolved single-engine pocketed drive lines. We have utilized cold-molded techniques to recreate the hull bottoms. We are coating everything with epoxy. We took lines off both boats and are digitizing jigs to reconstruct the houses, decks, and fly bridge with core cell foam. If we can keep the weights limited to 15,000 pounds, we will have impressive performance.

“Our new propeller pockets will allow a shaft angle of less than four degrees. I don’t know of any diesel inboard powerboat (without pods) with such a shallow shaft angle. We are hoping for cruise speeds in the 27-knot range and therefore have attempted to stiffen the hulls by 40 percent to accept the higher bottom loads. John Bildahl has shot over 1000 images so far, and we are very happy having him document our progress every day. We should finish exterior hull lamination within two weeks and roll the boats over to begin drive line installation shortly thereafter. We are hoping to achieve a unique blend of classic style, low maintenance and outstanding performance.”

Jake Glover of Ferry Point Marina in Trappe, MD, has stayed busy this winter. “We have a custom 32-foot bay boat in for a number of updates. She will receive a new Garmin electronics package, Lewmar windlass, and Jabsco sanitation system just to name a few. We also have a couple of new AwlGrip paint jobs to knock out before spring as well as a number of Interlux InterProtect and Bottom Paint systems to have ready for launch. Our north bulkhead replacement is complete! We will have an open house on April 2.”

Rob Hardy of Composite Yacht in Trappe, MD, has also had a busy winter. “We’ve been lucky to have a wide range of projects to keep us busy here at Composite Yacht. We’ve done several repowers, as well as numerous fabrication projects ranging from wind tunnel parts to a large hardtop and cabin extension on a DeFever 49. Our paint department stays busy year round, and we have several builds underway, on both our Chesapeake Bay and Offshore platforms. We’re also plugging away (pun intended) on the plug for the all new Offshore 32, which we’re very excited about. We hope to have a completed hull mold within the next month or so.”

Smoky Glover of Willard Marine in Virginia Beach, VA, reports in. “The SeaArk Commander Fire and Rescue boat belonging to the Avenue MD Volunteer Fire and Rescue Department is currently undergoing repower, repaint, structural, mechanical and electrical repair and upgrades to the firefighting system at the Willard Marine facility in Virginia Beach VA. New Yamaha outboards will be installed, along with a new fire pump and monitor… Willard Marine now owns rights to the SeaArk Marine line of commercial and government boats.”

Smoky Glover of Willard Marine in Virginia Beach, VA, reports in. “The SeaArk Commander Fire and Rescue boat belonging to the Avenue MD Volunteer Fire and Rescue Department is currently undergoing repower, repaint, structural, mechanical and electrical repair and upgrades to the firefighting system at the Willard Marine facility in Virginia Beach VA. New Yamaha outboards will be installed, along with a new fire pump and monitor… Willard Marine now owns rights to the SeaArk Marine line of commercial and government boats.”

Patrick Callahan at Worton Creek Marina in Chestertown, MD, sends us this update: “At Worton Creek we have fabricated and installed a custom hardtop on the aft deck of a 47-foot trawler. The aluminum railing is being extended around the top deck to include the hardtop. When complete, the hard top will have a freshly applied non-skid surface on top and new overhead lighting below. We also have several other fabrication and paint jobs going on.”

We are pleased to welcome a new contributor, Forrester Boatworks of Suffolk, VA, this month. “My name is Carson Forrester, and I am a small boat builder. I am currently building a small 17-foot skiff. I have two mate boats to build after this one is completed.”

Jonathon Newton of Hartge Yacht Yard in Galesville, MD, reports on a busy winter. “The mild weather of late fall and early winter really helped us get a good start to our busy winter. The buy boat Muriel Eileen is back together and in the water. New and old pieces in the shaft log area were re-secured with custom-made bronze bolts to replace the wasted away iron drifts and bolts. Not wanting large washers and nuts protruding from the bottom, some bolts were welded to plates that neatly fit to the deadrise and buttocks lines. The interior, aft of the engine and around the stuffing box, is mostly reassembled and being painted. Before long we will be starting on the sampson posts and chunk stern—a term for round sterns built from chunks of wood stacked like bricks and drift pinned together.”

Patrick Callahan at Worton Creek Marina in Chestertown, MD, sends us this update: “At Worton Creek we have fabricated and installed a custom hardtop on the aft deck of a 47-foot trawler. The aluminum railing is being extended around the top deck to include the hardtop. When complete, the hard top will have a freshly applied non-skid surface on top and new overhead lighting below. We also have several other fabrication and paint jobs going on.”

We are pleased to welcome a new contributor, Forrester Boatworks of Suffolk, VA, this month. “My name is Carson Forrester, and I am a small boat builder. I am currently building a small 17-foot skiff. I have two mate boats to build after this one is completed.”

Jonathon Newton of Hartge Yacht Yard in Galesville, MD, reports on a busy winter. “The mild weather of late fall and early winter really helped us get a good start to our busy winter. The buy boat Muriel Eileen is back together and in the water. New and old pieces in the shaft log area were re-secured with custom-made bronze bolts to replace the wasted away iron drifts and bolts. Not wanting large washers and nuts protruding from the bottom, some bolts were welded to plates that neatly fit to the deadrise and buttocks lines. The interior, aft of the engine and around the stuffing box, is mostly reassembled and being painted. Before long we will be starting on the sampson posts and chunk stern—a term for round sterns built from chunks of wood stacked like bricks and drift pinned together.”

On the other side of Galesville, Nancy Bray Booth of Hartge Yacht Harbor is also staying busy. “From bow to stern, Hartge Yacht Harbor is preparing to paint a 51-foot Dettling motor yacht inside the paint building. This yacht will take extensive sanding and preparation and will eventually have a new Awlgrip Stars n’ Stripes blue hull with off-white decks and cabin. By the time this winter is over, she will be looking good and ready for cruising. This boat is one of several Awlgrip paint jobs that we will be doing this winter and spring. We just completed an Awlgrip hull paint job in Flag Blue on a Swan 44.”

On the other side of Galesville, Nancy Bray Booth of Hartge Yacht Harbor is also staying busy. “From bow to stern, Hartge Yacht Harbor is preparing to paint a 51-foot Dettling motor yacht inside the paint building. This yacht will take extensive sanding and preparation and will eventually have a new Awlgrip Stars n’ Stripes blue hull with off-white decks and cabin. By the time this winter is over, she will be looking good and ready for cruising. This boat is one of several Awlgrip paint jobs that we will be doing this winter and spring. We just completed an Awlgrip hull paint job in Flag Blue on a Swan 44.”

From Denton MD, Meg Roney of Mathews Brothers Boatworks has had a busy winter as well. “Spring is almost here! It’s been a cold winter, but we’ve kept warm this winter by working on several major jobs in addition to the minor repairs on our storage boats so they are ready to go when boating season arrives. We have a Wilbur 34 in the shop with the engine pulled out while we replace the fuel tanks and clean up the bilge. Our varnish crew finished up a complete strip and rebuild varnish job on a Hinckley 36 and is working through maintenance coats on the rest of our storage boats.

“The guys are in the process of prepping another boat for paint after moving the Hinckley out of the paint booth. Some of the minor repairs we’ve done include replacing windshield gasket and hinges, fixing a cracked bowsprit, replacing a faulty float switch, and replacing control cables. The pilothouse on the buy boat Crow Bros II is coming along—the tongue and groove overhead is almost complete. We’re in the middle of glassing the cabin walls and will start the V planking shortly. Down at the landing, the insides of the buy boat hull have been painted, and the steering system is well under way.”

From Denton MD, Meg Roney of Mathews Brothers Boatworks has had a busy winter as well. “Spring is almost here! It’s been a cold winter, but we’ve kept warm this winter by working on several major jobs in addition to the minor repairs on our storage boats so they are ready to go when boating season arrives. We have a Wilbur 34 in the shop with the engine pulled out while we replace the fuel tanks and clean up the bilge. Our varnish crew finished up a complete strip and rebuild varnish job on a Hinckley 36 and is working through maintenance coats on the rest of our storage boats.

“The guys are in the process of prepping another boat for paint after moving the Hinckley out of the paint booth. Some of the minor repairs we’ve done include replacing windshield gasket and hinges, fixing a cracked bowsprit, replacing a faulty float switch, and replacing control cables. The pilothouse on the buy boat Crow Bros II is coming along—the tongue and groove overhead is almost complete. We’re in the middle of glassing the cabin walls and will start the V planking shortly. Down at the landing, the insides of the buy boat hull have been painted, and the steering system is well under way.”

Lauren Distefano of Bluewater Yacht Yards in Hampton, VA, reports. “One of our big projects we are working on is Sea Toy, a 59-foot Spencer yacht. She’s arguably one of the East Coast’s most popular and well known charter boats run by Captain Bull Tollson. Her complete engine re-power requires disassembly of the interior, removing couches, carpet, and salon door and removal of salon floor hatches; and removal of reverse gears from engines and engine accessories as needed for clearance. Then we reassemble engines, install new engine controls and displays, align engines, run new harnesses, and make all connections. Sea trials and reassembly of the interior to original condition will complete the job. A Sea Keeper installation as well as an all over paint job will put the final touches on the job.”

Lauren Distefano of Bluewater Yacht Yards in Hampton, VA, reports. “One of our big projects we are working on is Sea Toy, a 59-foot Spencer yacht. She’s arguably one of the East Coast’s most popular and well known charter boats run by Captain Bull Tollson. Her complete engine re-power requires disassembly of the interior, removing couches, carpet, and salon door and removal of salon floor hatches; and removal of reverse gears from engines and engine accessories as needed for clearance. Then we reassemble engines, install new engine controls and displays, align engines, run new harnesses, and make all connections. Sea trials and reassembly of the interior to original condition will complete the job. A Sea Keeper installation as well as an all over paint job will put the final touches on the job.”

Tracey Johns of the Chesapeake Bay Maritime Museum in St. Michaels, MD, sends us this report for the month. “Chesapeake Bay Maritime Museum’s Jenn Kuhn reports Pin Tail, a 25-foot Hooper Island Draketail, is now under construction in the boat shop. Built by CBMM’s Apprentice for a Day (AFAD) public boat building program participants, the build will continue through this spring, with the hull completed in June with the engine install and launch anticipated for late August. The boat features a reverse-rake round stern which is also referred to locally as a “torpedo stern,” “dovetail,” or “ducktail.” These were the first types of power workboats developed in the Chesapeake Bay region, having their heyday in the ‘20s and going out of style in the ‘40s when crab-potting became legal.

Tracey Johns of the Chesapeake Bay Maritime Museum in St. Michaels, MD, sends us this report for the month. “Chesapeake Bay Maritime Museum’s Jenn Kuhn reports Pin Tail, a 25-foot Hooper Island Draketail, is now under construction in the boat shop. Built by CBMM’s Apprentice for a Day (AFAD) public boat building program participants, the build will continue through this spring, with the hull completed in June with the engine install and launch anticipated for late August. The boat features a reverse-rake round stern which is also referred to locally as a “torpedo stern,” “dovetail,” or “ducktail.” These were the first types of power workboats developed in the Chesapeake Bay region, having their heyday in the ‘20s and going out of style in the ‘40s when crab-potting became legal.

“The Pin Tail is being built using plank-on-frame and started upside down on a strong-back. The bottom will be traditionally cross-planked with bead and cove strip planking for the topsides. White oak is being used for the keel, stem, chines, rails, and bed logs. Atlantic white cedar is being used for planking, with locust used for the knees and breast hook. The finished boat will be available for purchase, with proceeds supporting the boat restoration projects of the museum. The public can join in on the build throughout the process for one or more AFAD sessions, which take place on weekends through June. CBMM is offering a reduced $25 participation fee the third Saturday of each month. For more information or to register, email Jenn Kuhn at [email protected].”

Tammy Eaton of Judge Yachts in Denton, MD, winds up our month with a newsy and enthusiastic report: “Wow—what don’t we have going on this month? The crew continues to work on the several 36s and 27s we have going as well as preparing for our Open House on February 20. Along with all the other beautiful boats featured at our Open House, from our center consoles to the Chesapeakes, will be the Chesapeake 36 with Twins and the 36 with Triple Suzukis. Getting all of those boats prepared and staged so as to allow our attendees the chance to climb aboard and explore them takes a little finesse and finagling, but they always get it done. Finally for those clients that have their boats in storage with us, we are working on upgrades, additions, and maintenance. Gotta get those Judges ready for Spring!”

We are pleased to welcome another new contributor this month. Chad Brenner from Classic Restoration & Supply in Vintage Craft Boats in Philadelphia, PA, sends us this report. “We are currently working on a bunch of projects, some to include a 25 foot Chris Craft Sea Skiff in for a new paint job, along with some mechanicals and underwater hardware replacement. Alongside the Chris Craft we have a 1985 Donzi. We just re-gelcoated the whole boat, wet sanded and buffed and we are getting ready for delivery.”

“The Pin Tail is being built using plank-on-frame and started upside down on a strong-back. The bottom will be traditionally cross-planked with bead and cove strip planking for the topsides. White oak is being used for the keel, stem, chines, rails, and bed logs. Atlantic white cedar is being used for planking, with locust used for the knees and breast hook. The finished boat will be available for purchase, with proceeds supporting the boat restoration projects of the museum. The public can join in on the build throughout the process for one or more AFAD sessions, which take place on weekends through June. CBMM is offering a reduced $25 participation fee the third Saturday of each month. For more information or to register, email Jenn Kuhn at [email protected].”

Tammy Eaton of Judge Yachts in Denton, MD, winds up our month with a newsy and enthusiastic report: “Wow—what don’t we have going on this month? The crew continues to work on the several 36s and 27s we have going as well as preparing for our Open House on February 20. Along with all the other beautiful boats featured at our Open House, from our center consoles to the Chesapeakes, will be the Chesapeake 36 with Twins and the 36 with Triple Suzukis. Getting all of those boats prepared and staged so as to allow our attendees the chance to climb aboard and explore them takes a little finesse and finagling, but they always get it done. Finally for those clients that have their boats in storage with us, we are working on upgrades, additions, and maintenance. Gotta get those Judges ready for Spring!”

We are pleased to welcome another new contributor this month. Chad Brenner from Classic Restoration & Supply in Vintage Craft Boats in Philadelphia, PA, sends us this report. “We are currently working on a bunch of projects, some to include a 25 foot Chris Craft Sea Skiff in for a new paint job, along with some mechanicals and underwater hardware replacement. Alongside the Chris Craft we have a 1985 Donzi. We just re-gelcoated the whole boat, wet sanded and buffed and we are getting ready for delivery.”

by Capt. Rick Franke

by Capt. Rick Franke