Summer is finally here. Chesapeake boatshops continue to hum with activity after a late, wet, and reluctant spring. The spring commissioning rush blends seamlessly into summer’s work, and boatshops report with their favorite word: busy!

Rob Hardy of Composite Yacht in Trappe, MD, sets the tone for the summer in this report. “Like everyone else, we’re still wide open here at CY. We’re about to ship a 26 to Hawaii. We’re nearing completion on another Chesapeake Bay style 26 with a cruising cabin and have another CY26C in the mold to be finished as a light-tackle center console. We also have a 46 underway in the mold. Our metal fabricators have been working steadily on a number of fab projects, and our paint shop is in constant rotation. The laminate shop has also been pumping out a number of hard tops for multiple applications, including a complex top for a cruising catamaran that incorporates retractable sun roofs. Add all the day-to-day service work and repowers, and we’re humming along as quickly as we can go.”

[gallery type="square" link="file" ids="14911,14916"]

Lauren Distefano of Bluewater Yacht Yards in Hampton, VA, brings us up to date. “Our boat yard is still steadily moving boats in and out of the yard to keep our customers out on the water for fishing season with paint jobs, to include topsides, hull, and cockpits. Our yard completed commissioning and outfitting, to include main frame electronics, on a 48-foot 2016 Sabre yacht. We recently finished a faux teak transom with an airbrushed name with silver leaf outline on a 60-foot B&D Boat Works.”

Meg Roney checks in with the latest from Mathews Brothers in Denton MD

Meg Roney checks in with the latest from Mathews Brothers in Denton MD. “The unusually wet spring has stretched our spring deliveries due to people understandably wanting to wait for drier weather. Hopefully summer will be dry enough to enjoy the use of their boats! At Mathews Landing, systems are well underway in the buy boat. The engine, generator, and fuel tanks were all installed by mid-May. They’re running plumbing, wiring, and hydraulics now. This boat gets extensive hydraulics with hydraulic windlass and bow thruster as well as steering. We’ve had good turnouts at our Nautical Flea Markets down at Mathews Landing. We’re holding them on the first and third Saturdays each month, and the Landing is open Thursdays and Fridays most weeks. Consignments are most welcome. We’re offering free table space for a limited time, so come see us! We are in the process of lining up several other projects for the rest of the year—more details next month.”

Chad Brenner from Classic Restoration and Supply in Philadelphia, PA, has a busy summer planned. “As summer is here, we are working on an engine replacement on a 26-foot runabout, along with building a 26-foot electric-powered runabout for Omega Yachts. Also working on a 1947 Garwood sedan (Last One) getting it ready for delivery.”

Nancy Bray Booth at Hartge Yacht Harbor in Galesville, MD

Nancy Bray Booth at Hartge Yacht Harbor in Galesville, MD, has had a busy spring as well. “At Hartge Yacht Harbor we have been busy with spring boat preparations. Despite the challenging weather, we have managed to launch everyone in time for boating season. We have peeled the paint off the bottom of five boats so far this spring. There has been the usual rush to get hull sides waxed and bottoms painted. In June, we will be painting the hull sides of a Regulator 25 and painting the decks on a custom 36-foot sport fish.

Fuel cleaning/polishing has been very popular with great results. Our fuel polishing system has been used nonstop all spring. We work with each customer by taking samples and determining the condition of the fuel. If the fuel requires filtering, we complete that along with the cleaning of the tank. Clean fuel is imperative for proper engine function.

The HYH mechanics have pulled a Perkins 4018 engine with a failed transmission, which turned into a minor overhaul. The injection pump and injectors had to be replaced, and it required a complete gasket replacement, including front and rear seals. In the works is a removal of an old Universal 5444 and replacing it with a Yanmar 4JH Series engine. Sometimes it’s more economical and more efficient to replace an engine rather than try to resurrect it, and we review each situation to make the best decision for each boat.”

Dave Hannam with Classic Watercraft Restoration in Annapolis

Dave Hannam with Classic Watercraft Restoration in Annapolis, reports the shop has been busy getting his customers old woodies ready to show in the Antique and Classic Boat Festival June 17-19 in St. Michaels. The Gar Wood 16 foot replica speedster 220-hp, 262 CID V6 hot rod engine is purring nicely and the 1950s Custom 17-foot white hulled/fire engine red bottom runabout has all new coatings, upgrades to mechanical and electrical components and will be ready for its sea trial prior to the upcoming classic boat event on Father’s Day weekend!

[gallery type="square" link="file" ids="14917,14915"]

Jake Glover of Ferry Point Marina in Trappe, MD, sends us this update. “The crew has completed a new sanitation system install, electronics upgrade, and a variety of other upgrades to a 32-foot Charter Style Bay Boat. Collision repairs are coming in as fast as they go out. A 48-foot Carver and 41-foot Cruiser Yacht both received repairs to rotten foredecks, and the mechanics are staying busy with service and repair orders. Our new lifts and slips sold out quickly this spring with more renovations planned for this winter.”

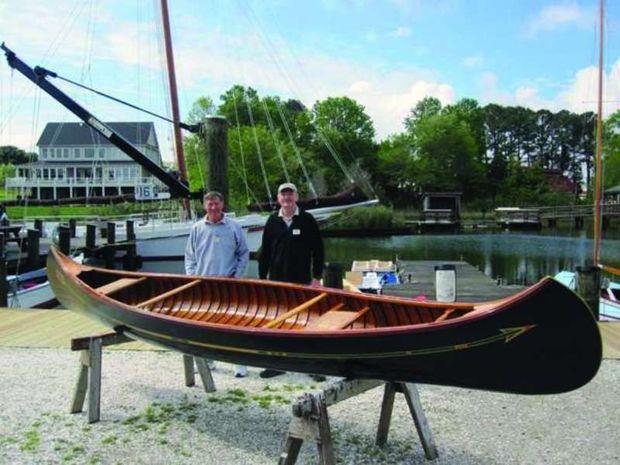

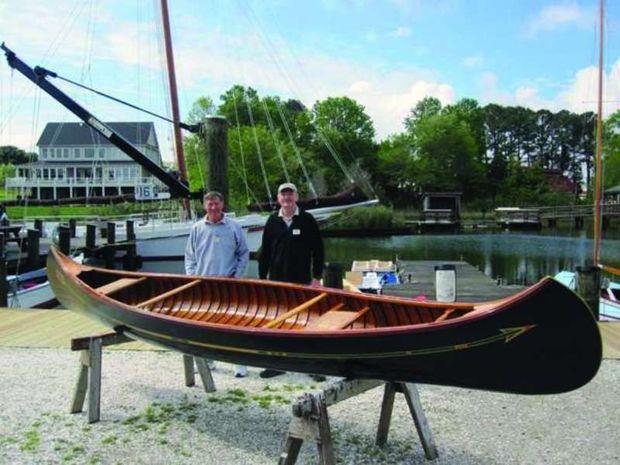

Traci Cimini of the Calvert Marine Museum in Solomons, MD, reports. “The Patuxent Small Craft Guild (PSCG) members were very busy over the winter and completed many projects, one of which was the restoration of a 1925 Kennebec Wood and Canvas Canoe. This beautiful antique boat is selling for $2500 with all proceeds benefitting the museum activities supported by the Guild. For more details, please contact George Surgent at (410) 586-2700.

Joe Connor of the Chesapeake Bay Maritime Museum (CBMM) in St. Michaels, MD

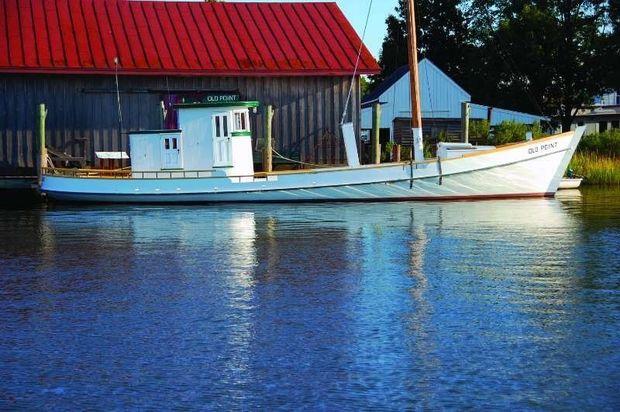

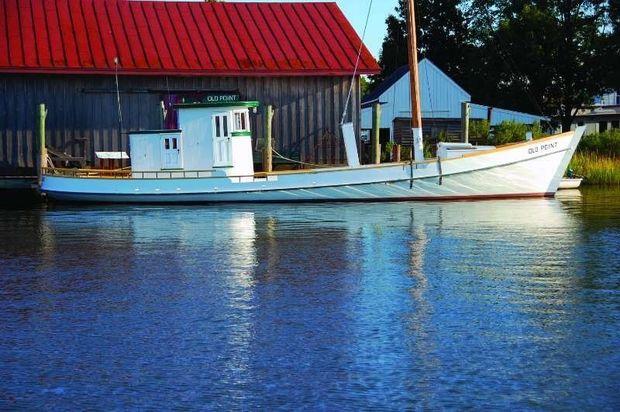

Joe Connor of the Chesapeake Bay Maritime Museum (CBMM) in St. Michaels, MD, reports: “CBMM’s boatshop has recently partnered with Chesapeake Community College welding instructor Mike Lyons to restore the crab dredging rig of the 1909 crab dredger

Old Point. An old dredging rig was salvaged from wreckage outside of Poquoson, VA, by CBMM assistant curator of watercraft Richard Scofield more than a decade ago to use for the historic boat. The rollers were fitted to a larger vessel and needed to be cut down and welded to fit

Old Point.

Recently, boat shop volunteer Jim Meholic spearheaded the Chesapeake College collaboration, and in utilizing Lyons’ metal fabrication expertise, the new rollers have been fabricated for the rig and are currently back at the museum where they will be fitted to

Old Point later this summer.

Old Point was one of a fleet of crab dredging boats that operated out of Hampton, VA, at the mouth of the Chesapeake Bay from the 1910s through the 1960s. From December through March, captains and crews lived on their boats so they could leave early every morning and dredge for crabs all day.

In the summer and fall,

Old Point carried fish and oysters to packing houses or to market.

Old Point’s hull was built the old-fashioned way, hewn from seven pine logs. At that time big logs were hard to get, but watermen still preferred a solid log boat if they could get one.

Old Point was donated to CBMM in 1984, a gift of Mr. and Mrs. Richard C. duPont. For more information, visit

cbmm.org or call (410) 745-291.

Carson Forrester of Forrester Boatworks in Suffolk, VA, has also been busy this spring. “The guys at Forrester Boatworks are finishing up the custom 17-foot Trout skiff to be used as a demo boat until it sells. The boat will be available to see and demo in about a month. FBW also just took a deposit on building a 21-foot center console guide boat for Wingman Guide Services, and we are really excited about the project. This will be a cold-molded, jig-built, shallow-draft center console. We will start setting up the jig in the next couple of weeks!”

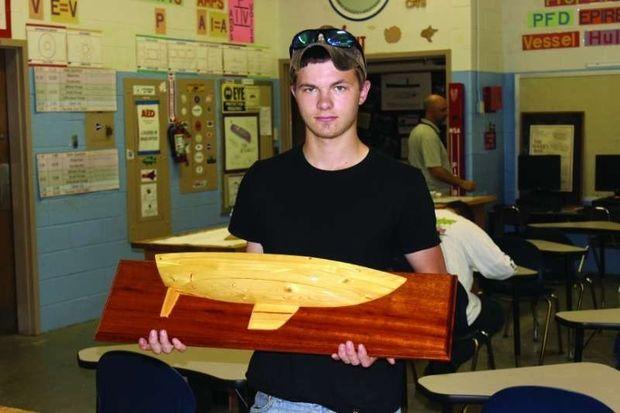

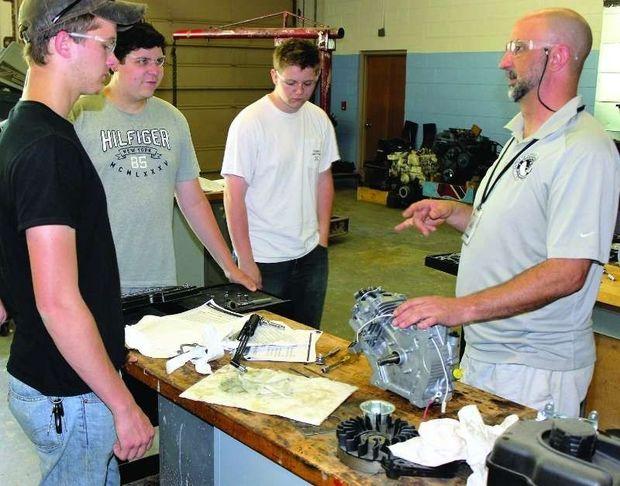

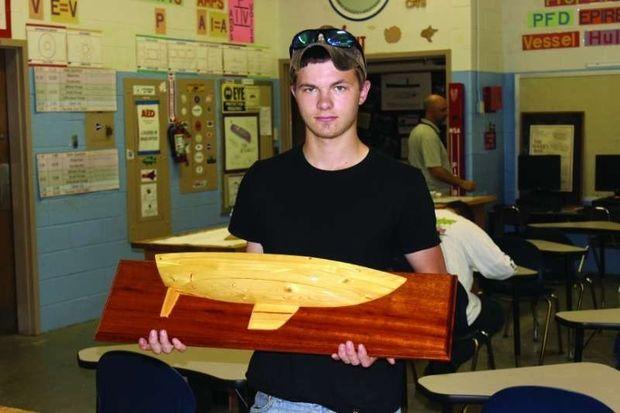

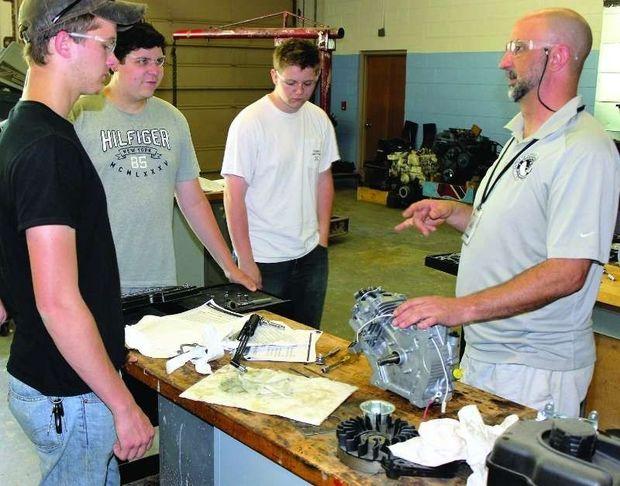

Since press time for this issue occurs just about the time our public school term ends, I stopped by the

Center of Applied Technology in Edgewater, MD, to visit with instructor Dave Fawley. I was especially interested to see how much progress they had made on the John Harris-designed 23-foot, cold-molded, custom motor launch that was this year’s major project for his class. Dave explained that the cold molding process was now complete, and he hoped to have the hull off the jigs and glassed by the end of this school year.

The challenge of turning a custom set of drawings into a real boat was a positive challenge for the class. Several of the students pointed out the complex curves in the stem and forward area of the hull and told me about the difficulty of “getting it right” in the plywood molding process. They, and Dave, were proud of the finished product and rightfully so. Dave also explained that the venture into cold molding afforded the opportunity to see the process in a working boat factory when the class did a field trip to Weaver Boatworks in Deale, MD. Dave also mentioned that three of his students have been accepted into the pre-apprenticeship program conducted by the Marine Trades Association of Maryland and will be working in the industry this summer.

by Captain Rick Franke

by Captain Rick Franke Meg Roney checks in with the latest from Mathews Brothers in Denton MD. “The unusually wet spring has stretched our spring deliveries due to people understandably wanting to wait for drier weather. Hopefully summer will be dry enough to enjoy the use of their boats! At Mathews Landing, systems are well underway in the buy boat. The engine, generator, and fuel tanks were all installed by mid-May. They’re running plumbing, wiring, and hydraulics now. This boat gets extensive hydraulics with hydraulic windlass and bow thruster as well as steering. We’ve had good turnouts at our Nautical Flea Markets down at Mathews Landing. We’re holding them on the first and third Saturdays each month, and the Landing is open Thursdays and Fridays most weeks. Consignments are most welcome. We’re offering free table space for a limited time, so come see us! We are in the process of lining up several other projects for the rest of the year—more details next month.”

Chad Brenner from Classic Restoration and Supply in Philadelphia, PA, has a busy summer planned. “As summer is here, we are working on an engine replacement on a 26-foot runabout, along with building a 26-foot electric-powered runabout for Omega Yachts. Also working on a 1947 Garwood sedan (Last One) getting it ready for delivery.”

Meg Roney checks in with the latest from Mathews Brothers in Denton MD. “The unusually wet spring has stretched our spring deliveries due to people understandably wanting to wait for drier weather. Hopefully summer will be dry enough to enjoy the use of their boats! At Mathews Landing, systems are well underway in the buy boat. The engine, generator, and fuel tanks were all installed by mid-May. They’re running plumbing, wiring, and hydraulics now. This boat gets extensive hydraulics with hydraulic windlass and bow thruster as well as steering. We’ve had good turnouts at our Nautical Flea Markets down at Mathews Landing. We’re holding them on the first and third Saturdays each month, and the Landing is open Thursdays and Fridays most weeks. Consignments are most welcome. We’re offering free table space for a limited time, so come see us! We are in the process of lining up several other projects for the rest of the year—more details next month.”

Chad Brenner from Classic Restoration and Supply in Philadelphia, PA, has a busy summer planned. “As summer is here, we are working on an engine replacement on a 26-foot runabout, along with building a 26-foot electric-powered runabout for Omega Yachts. Also working on a 1947 Garwood sedan (Last One) getting it ready for delivery.”

Nancy Bray Booth at Hartge Yacht Harbor in Galesville, MD, has had a busy spring as well. “At Hartge Yacht Harbor we have been busy with spring boat preparations. Despite the challenging weather, we have managed to launch everyone in time for boating season. We have peeled the paint off the bottom of five boats so far this spring. There has been the usual rush to get hull sides waxed and bottoms painted. In June, we will be painting the hull sides of a Regulator 25 and painting the decks on a custom 36-foot sport fish.

Fuel cleaning/polishing has been very popular with great results. Our fuel polishing system has been used nonstop all spring. We work with each customer by taking samples and determining the condition of the fuel. If the fuel requires filtering, we complete that along with the cleaning of the tank. Clean fuel is imperative for proper engine function.

The HYH mechanics have pulled a Perkins 4018 engine with a failed transmission, which turned into a minor overhaul. The injection pump and injectors had to be replaced, and it required a complete gasket replacement, including front and rear seals. In the works is a removal of an old Universal 5444 and replacing it with a Yanmar 4JH Series engine. Sometimes it’s more economical and more efficient to replace an engine rather than try to resurrect it, and we review each situation to make the best decision for each boat.”

Nancy Bray Booth at Hartge Yacht Harbor in Galesville, MD, has had a busy spring as well. “At Hartge Yacht Harbor we have been busy with spring boat preparations. Despite the challenging weather, we have managed to launch everyone in time for boating season. We have peeled the paint off the bottom of five boats so far this spring. There has been the usual rush to get hull sides waxed and bottoms painted. In June, we will be painting the hull sides of a Regulator 25 and painting the decks on a custom 36-foot sport fish.

Fuel cleaning/polishing has been very popular with great results. Our fuel polishing system has been used nonstop all spring. We work with each customer by taking samples and determining the condition of the fuel. If the fuel requires filtering, we complete that along with the cleaning of the tank. Clean fuel is imperative for proper engine function.

The HYH mechanics have pulled a Perkins 4018 engine with a failed transmission, which turned into a minor overhaul. The injection pump and injectors had to be replaced, and it required a complete gasket replacement, including front and rear seals. In the works is a removal of an old Universal 5444 and replacing it with a Yanmar 4JH Series engine. Sometimes it’s more economical and more efficient to replace an engine rather than try to resurrect it, and we review each situation to make the best decision for each boat.”

Dave Hannam with Classic Watercraft Restoration in Annapolis, reports the shop has been busy getting his customers old woodies ready to show in the Antique and Classic Boat Festival June 17-19 in St. Michaels. The Gar Wood 16 foot replica speedster 220-hp, 262 CID V6 hot rod engine is purring nicely and the 1950s Custom 17-foot white hulled/fire engine red bottom runabout has all new coatings, upgrades to mechanical and electrical components and will be ready for its sea trial prior to the upcoming classic boat event on Father’s Day weekend!

[gallery type="square" link="file" ids="14917,14915"]

Jake Glover of Ferry Point Marina in Trappe, MD, sends us this update. “The crew has completed a new sanitation system install, electronics upgrade, and a variety of other upgrades to a 32-foot Charter Style Bay Boat. Collision repairs are coming in as fast as they go out. A 48-foot Carver and 41-foot Cruiser Yacht both received repairs to rotten foredecks, and the mechanics are staying busy with service and repair orders. Our new lifts and slips sold out quickly this spring with more renovations planned for this winter.”

Traci Cimini of the Calvert Marine Museum in Solomons, MD, reports. “The Patuxent Small Craft Guild (PSCG) members were very busy over the winter and completed many projects, one of which was the restoration of a 1925 Kennebec Wood and Canvas Canoe. This beautiful antique boat is selling for $2500 with all proceeds benefitting the museum activities supported by the Guild. For more details, please contact George Surgent at (410) 586-2700.

Dave Hannam with Classic Watercraft Restoration in Annapolis, reports the shop has been busy getting his customers old woodies ready to show in the Antique and Classic Boat Festival June 17-19 in St. Michaels. The Gar Wood 16 foot replica speedster 220-hp, 262 CID V6 hot rod engine is purring nicely and the 1950s Custom 17-foot white hulled/fire engine red bottom runabout has all new coatings, upgrades to mechanical and electrical components and will be ready for its sea trial prior to the upcoming classic boat event on Father’s Day weekend!

[gallery type="square" link="file" ids="14917,14915"]

Jake Glover of Ferry Point Marina in Trappe, MD, sends us this update. “The crew has completed a new sanitation system install, electronics upgrade, and a variety of other upgrades to a 32-foot Charter Style Bay Boat. Collision repairs are coming in as fast as they go out. A 48-foot Carver and 41-foot Cruiser Yacht both received repairs to rotten foredecks, and the mechanics are staying busy with service and repair orders. Our new lifts and slips sold out quickly this spring with more renovations planned for this winter.”

Traci Cimini of the Calvert Marine Museum in Solomons, MD, reports. “The Patuxent Small Craft Guild (PSCG) members were very busy over the winter and completed many projects, one of which was the restoration of a 1925 Kennebec Wood and Canvas Canoe. This beautiful antique boat is selling for $2500 with all proceeds benefitting the museum activities supported by the Guild. For more details, please contact George Surgent at (410) 586-2700.

Joe Connor of the Chesapeake Bay Maritime Museum (CBMM) in St. Michaels, MD, reports: “CBMM’s boatshop has recently partnered with Chesapeake Community College welding instructor Mike Lyons to restore the crab dredging rig of the 1909 crab dredger Old Point. An old dredging rig was salvaged from wreckage outside of Poquoson, VA, by CBMM assistant curator of watercraft Richard Scofield more than a decade ago to use for the historic boat. The rollers were fitted to a larger vessel and needed to be cut down and welded to fit Old Point.

Recently, boat shop volunteer Jim Meholic spearheaded the Chesapeake College collaboration, and in utilizing Lyons’ metal fabrication expertise, the new rollers have been fabricated for the rig and are currently back at the museum where they will be fitted to Old Point later this summer. Old Point was one of a fleet of crab dredging boats that operated out of Hampton, VA, at the mouth of the Chesapeake Bay from the 1910s through the 1960s. From December through March, captains and crews lived on their boats so they could leave early every morning and dredge for crabs all day.

Joe Connor of the Chesapeake Bay Maritime Museum (CBMM) in St. Michaels, MD, reports: “CBMM’s boatshop has recently partnered with Chesapeake Community College welding instructor Mike Lyons to restore the crab dredging rig of the 1909 crab dredger Old Point. An old dredging rig was salvaged from wreckage outside of Poquoson, VA, by CBMM assistant curator of watercraft Richard Scofield more than a decade ago to use for the historic boat. The rollers were fitted to a larger vessel and needed to be cut down and welded to fit Old Point.

Recently, boat shop volunteer Jim Meholic spearheaded the Chesapeake College collaboration, and in utilizing Lyons’ metal fabrication expertise, the new rollers have been fabricated for the rig and are currently back at the museum where they will be fitted to Old Point later this summer. Old Point was one of a fleet of crab dredging boats that operated out of Hampton, VA, at the mouth of the Chesapeake Bay from the 1910s through the 1960s. From December through March, captains and crews lived on their boats so they could leave early every morning and dredge for crabs all day.

In the summer and fall, Old Point carried fish and oysters to packing houses or to market. Old Point’s hull was built the old-fashioned way, hewn from seven pine logs. At that time big logs were hard to get, but watermen still preferred a solid log boat if they could get one. Old Point was donated to CBMM in 1984, a gift of Mr. and Mrs. Richard C. duPont. For more information, visit cbmm.org or call (410) 745-291.

Carson Forrester of Forrester Boatworks in Suffolk, VA, has also been busy this spring. “The guys at Forrester Boatworks are finishing up the custom 17-foot Trout skiff to be used as a demo boat until it sells. The boat will be available to see and demo in about a month. FBW also just took a deposit on building a 21-foot center console guide boat for Wingman Guide Services, and we are really excited about the project. This will be a cold-molded, jig-built, shallow-draft center console. We will start setting up the jig in the next couple of weeks!”

Since press time for this issue occurs just about the time our public school term ends, I stopped by the Center of Applied Technology in Edgewater, MD, to visit with instructor Dave Fawley. I was especially interested to see how much progress they had made on the John Harris-designed 23-foot, cold-molded, custom motor launch that was this year’s major project for his class. Dave explained that the cold molding process was now complete, and he hoped to have the hull off the jigs and glassed by the end of this school year.

In the summer and fall, Old Point carried fish and oysters to packing houses or to market. Old Point’s hull was built the old-fashioned way, hewn from seven pine logs. At that time big logs were hard to get, but watermen still preferred a solid log boat if they could get one. Old Point was donated to CBMM in 1984, a gift of Mr. and Mrs. Richard C. duPont. For more information, visit cbmm.org or call (410) 745-291.

Carson Forrester of Forrester Boatworks in Suffolk, VA, has also been busy this spring. “The guys at Forrester Boatworks are finishing up the custom 17-foot Trout skiff to be used as a demo boat until it sells. The boat will be available to see and demo in about a month. FBW also just took a deposit on building a 21-foot center console guide boat for Wingman Guide Services, and we are really excited about the project. This will be a cold-molded, jig-built, shallow-draft center console. We will start setting up the jig in the next couple of weeks!”

Since press time for this issue occurs just about the time our public school term ends, I stopped by the Center of Applied Technology in Edgewater, MD, to visit with instructor Dave Fawley. I was especially interested to see how much progress they had made on the John Harris-designed 23-foot, cold-molded, custom motor launch that was this year’s major project for his class. Dave explained that the cold molding process was now complete, and he hoped to have the hull off the jigs and glassed by the end of this school year.

The challenge of turning a custom set of drawings into a real boat was a positive challenge for the class. Several of the students pointed out the complex curves in the stem and forward area of the hull and told me about the difficulty of “getting it right” in the plywood molding process. They, and Dave, were proud of the finished product and rightfully so. Dave also explained that the venture into cold molding afforded the opportunity to see the process in a working boat factory when the class did a field trip to Weaver Boatworks in Deale, MD. Dave also mentioned that three of his students have been accepted into the pre-apprenticeship program conducted by the Marine Trades Association of Maryland and will be working in the industry this summer.

The challenge of turning a custom set of drawings into a real boat was a positive challenge for the class. Several of the students pointed out the complex curves in the stem and forward area of the hull and told me about the difficulty of “getting it right” in the plywood molding process. They, and Dave, were proud of the finished product and rightfully so. Dave also explained that the venture into cold molding afforded the opportunity to see the process in a working boat factory when the class did a field trip to Weaver Boatworks in Deale, MD. Dave also mentioned that three of his students have been accepted into the pre-apprenticeship program conducted by the Marine Trades Association of Maryland and will be working in the industry this summer.

by Captain Rick Franke

by Captain Rick Franke