As summer officially begins, the turbulent economic situation continues to concern everyone in the industry. Last month we referred to the mood as cautious optimism. That feeling continues with perhaps a bit more caution. But new boats are being built and lots of repair and restoration work continues, so we will wait and see. In the meantime, congratulations and happy 20th birthday to PropTalk Magazine!

First up this month is an update from Jake Glover at Ferry Point Marina in Trappe, MD. “As usual for this time of year, our team of mechanics—including two master technicians—has been hard at work. We’re still getting a few late-season launches wrapped up and recently completed significant mechanical repairs on an 8.1 MerCruiser inside a beautiful Sea Ray 290 SDX. Another major project just finished: the installation of new forward fuel tanks on a 32-foot Albemarle. This vessel had its inboard engines removed last winter and was converted to outboard power with a custom bracket installation.

"Our paint crew has been steadily tackling seasonal gelcoat and paint touch-ups. Painting outboards continues to be a popular option, with several completed already this season. We’re also happy to report that our brand-new fuel system has been staying busy with steady boat traffic. And don’t forget, our fully stocked ship’s store has everything you need: ice, cold drinks and beer, snacks, ice cream, bait, tackle, and parts. Keep our mobile detailers and marine A/C techs in mind!”

Andy Dize of Roudebush Yacht and Engine Works in Dundalk, MD, brings us up to date. “The summer boating season is now in full swing at RY&EW. Although there is not a lot to report this month, we have a couple of ongoing projects and a few on the books to begin later this year. We are also in the middle of getting the last few storage boats off the hard. Work for these boats includes minor engine, electrical, and plumbing repairs with all getting a splash of bottom paint before going in. We are deep into the production of our first aluminum build for Hull number one of a 28-foot aluminum dive support boat. Hull number one is in outfitting with Hull number two in fabrication.

“To keep us busy for the summer, we picked up a re-engine job on a 41-foot utility boat replacing two older eight-cylinder Cummins diesel engines with two new six-cylinder turbocharged diesels for a local government client. We are also continuing the disposal of several derelict boats as well as upgrading our fixed docks with floating docks. A future project, in client discussion, is for building a new fiberglass hard top for a 42-foot boat. RY&EW is a full-service marina able to dock, lift, and repair boats up to 44 feet. Please reach out to Andy to discuss your future boat repair or new construction needs.”

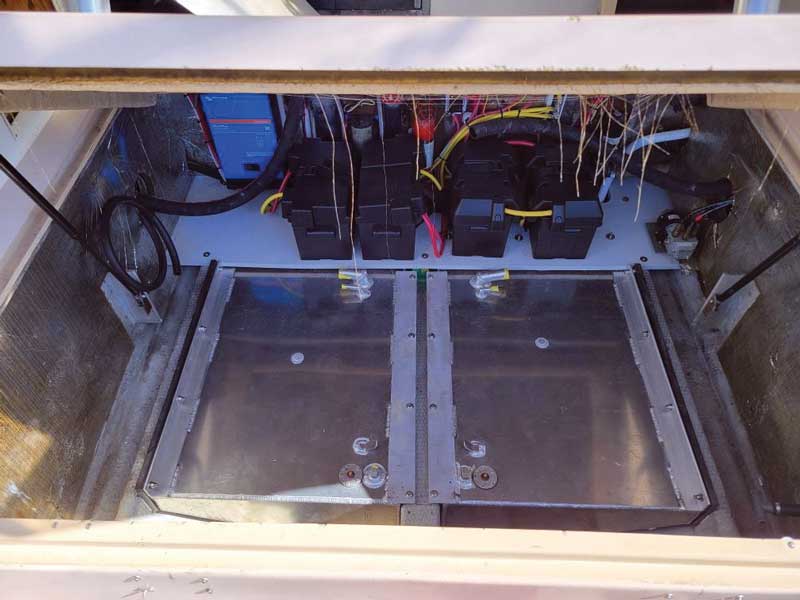

Tiffany Yachts of Burgess, VA, recently reported on a unique project via their Facebook page. “We recently completed a custom lithium battery and inverter setup on a 53-foot Selene that will run the boat for a night on the hook. Solar panels on the bimini top and Victron Inverters and monitoring devices complete the installation. If you are in need of custom work of any kind, call us today to discuss your next project.”

Eric Detweiler from the Chesapeake Bay Maritime Museum (CBMM) in St. Michaels, MD, checks in with a newsy report. “Jay Williams, vice president of shipyard and marine operations, reports that it’s been a busy spring around CBMM’s shipyard. Tall ship Providence is at our docks throughout early summer for work on its mast, rig, and railings. Led by vessel conservation manager Sam Hilgartner, our riggers will work to drop its yard and crane iron to the deck and begin the process of prep for a later replacement of the mast. Meanwhile, shipwrights will be replacing sections of its railings, shaping and building a new Samson post, and replacing its mast partner wedges. Tall Ship Sultana has been at our docks hosting youth programming, and while here, our team has performed a scheduled rig and mast inspection.

“Unless you worked as a waterman before 1965, you’ve never seen a 23-foot Hoopers Island Sharpie. We’re resurrecting the species on the shop floor, building a new one from scratch. Currently, it’s just a station diagram, but once the plans arrive from the Smithsonian, we’ll be milling lumber to build this historic vessel. This vessel will take shape throughout the summer season, hopefully with a debut at Sultana Downrigging Festival. It will have a removable cuddy cabin, a two-masted rig, and plenty of room for a family weekend. It will be exciting to see this lost design sailing the Chesapeake once again.

“Speaking of resurrected boats, CBMM can build your dream sharpie, skipjack, crab skiff, buyboat, or deadrise from historical plans. For less money than a new plastic center console of the same size, you can have a truly unique Chesapeake workboat, built to your specifications from our historical plans. If you dream of your own sharpie, we can make it happen. Email Jay Williams at [email protected] to learn more.

“Under the direction of shipwright educator Steve Garrand, CBMM’s newest apprentices, Austin Benshoff and Caden Lewis, are nearing completion on a Pete Culler-designed ‘Good Little Skiff’ to begin their two-year program. They have been working since mid-January on this traditionally constructed, flat-bottom, Chesapeake-inspired rowing vessel.”

Rob Hardy of Composite Yacht in Trappe, MD, also reported on a current venture: “Project update! We’re cruising along on the CY46 based Research Vessel for the St. Mary’s College Marine Sciences Program. She will be powered by a pair of Cummins QSL’s and will have a cut down transom and a large, hydraulically actuated winch and gantry system to launch and retrieve research equipment.”

David Jr. from Evans Boats in Crisfield, MD, checks in with us. “Here at Evans Boats we are finding ourselves with a bit of a slowdown in the yard but continuing at a moderate pace. We have just launched a new Custom 50-foot Evans heading to Rhode Island next week for a young gentleman who sold his 38-foot Evans to upgrade to a larger vessel. We have also completed a Custom Navy Hull style boat that we will be placing on the market soon. Stay tuned to our Facebook page for more information on that. Additionally, we are wrapping up a few restoration jobs that required new cabins and fresh paint jobs. Now, we will focus our attention on completing a wooden Roundstern in which we will be laying fresh fiberglass on the sides with a fresh paint job, as well as the installation of a new shaft tube.”

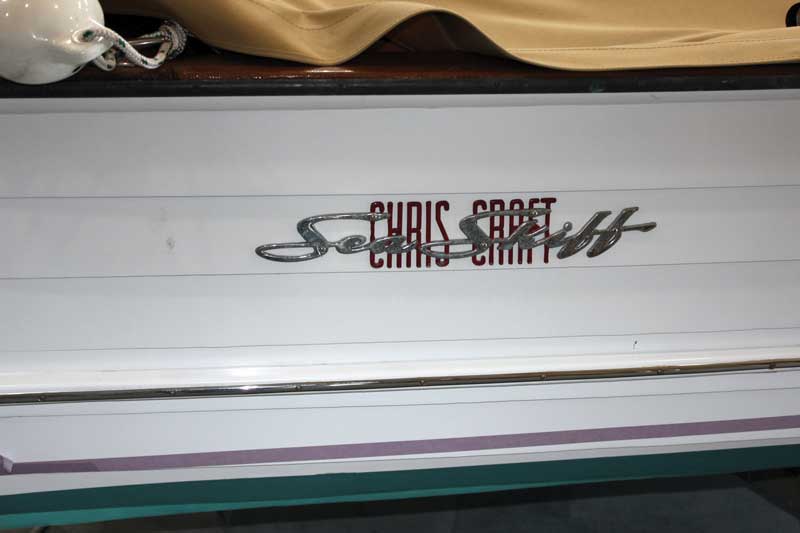

Buster Phipps at Phipps Boat Works in Deale, MD, has a 1954 Chris-Craft Sea Skiff in the shop for some varnish work. This boat is unique in that it sports the super rare first logo for the Sea Skiffs which was only used on boats from the early 1950s (see photo).

And, last but not least, we hear from Hank Reiser of Marine Services LLC at Pocahontas Marina in Edgewater, MD. “The 1956 26-foot Chris-Craft Sea Skiff is in for a bottom job, some minor repairs, and lots of varnish work. On The 26-foot Lyman, we just completed an Awlgrip job, some assembling of hardware, and some running gear work. The 1933 16-foot Chris-Craft Race Boat Special in the shop is almost complete; we are just completing the assembly on that. The engine is in, and the new dashboard is in and hooked up, and everything works. We have several interior trim panels and a cockpit hard top from the Midnight Lace in the shop. The boat has gone home to her owner. We are staying very busy with repair and restoration work.”

Well, that’s it for now. Remember to recycle your used shrinkwrap (last reminder, I promise!). Enjoy your boat and the Bay, and we will see you next month.