What does it mean for your diesel engine?

What does it mean for your diesel engine?

I receive emails and questions during lectures from savvy boat owners on this subject again and again, and the volume of discussion on this issue is only exceeded by the confusion, concern, and lack of understanding it generates.

I read a boat review a few years back, in which the reviewer boasted that “…because the [subject vessel] achieved cruising speed while using only a fraction of the engine’s available power, the engine should therefore last forever.” It’s a concept that’s commonly misunderstood, and one that seems counterintuitive: the lighter the load on your engine, the greater the likelihood of developing problems. It’s true: when a diesel engine is chronically under-loaded, several phenomena occur that conspire to shorten the life of the engine, reduce efficiency, and increase the need for maintenance and possible repairs.

The environment inside a diesel engine combustion chamber is a hellish one indeed. The temperature can reach over 1000 degrees Fahrenheit while the pressure may be many times that of the atmosphere outside the engine. Interestingly, however, this is how a diesel engine is designed to operate most efficiently, at comparatively high temperature under relatively high load. The high pressure found within the combustion chamber represents the very philosophy of the diesel ignition process: compressing the air increases its temperature, which in turn enables it to ignite the subsequently injected fuel. While I’ll be the first to recognize that it’s not always possible for recreational vessels to be operated in this manner, ideally, it’s best to size engines so they are run most often at something over 50 percent load, and preferably closer to 75 percent. When operated in this manner, the temperature within the engine ensures greater efficiency and improved longevity. Contrary to popular belief, while they may have improved defenses against it, new, electronically controlled engines are not immune from issues created by chronic under-loading. Furthermore, chronic engine over-sizing exacerbates the issue.

When discussing proper operating temperature, it’s important to remember that there are several regions within the engine, all of which are almost certainly operating at different temperatures, under differing load conditions. For instance, when you start your engine and run it at idle or at low rpm, you may notice that the temperature gauge that measures coolant temperature doesn’t move very much. If it’s graduated in numbers as it should be, it’s unlikely that the needle passes 145 degrees F.

On the other hand, when a load is applied, if you are motoring hard to make port before a weather system descends upon you, for instance, the needle should hover around the engine’s maximum design operating and thermostat opening temperature, which for closed cooling system engines is typically, depending on the engine’s design, between 160 degrees F and 195 degrees F. In the light load condition, when the coolant temperature is low, it means the temperature of the combustion chamber is also lower than that which is optimal. This leads to the formation of excess soot or carbon, which is deposited on the piston rings, injectors, and valves, a scenario which reduces efficiency and may shorten the life of these components.

Cylinder wall glazing, which exacerbates blow by, also occurs when an engine is chronically under loaded, especially early on in its life. Because they are often chronically under loaded in the critical break-in period, the first 50-100 hours, generators are notorious for suffering from this malady.

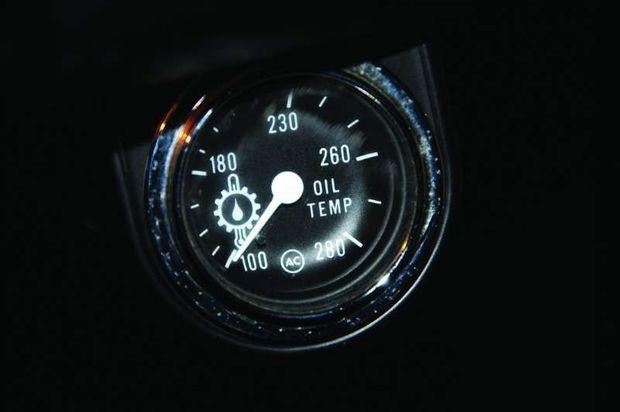

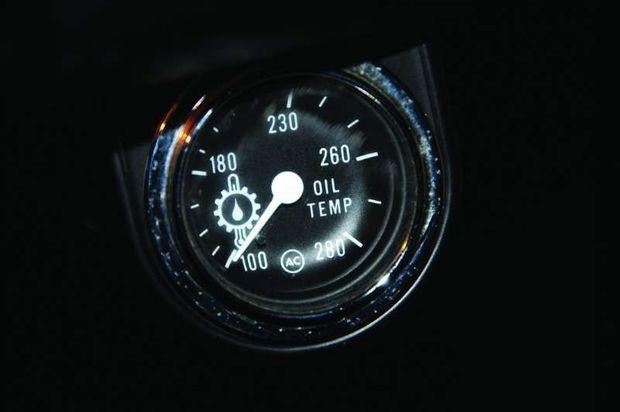

Even under moderate load, when the coolant reaches a normal operating temperature, unless the engine is equipped with an oil cooler thermostat, the oil temperature often remains cooler, too cool for optimum operation. This is a significant and often overlooked aspect of under-loading, and it isn’t mitigated by electronic, computer-controlled, diesel-fuel injection systems. Few engines are equipped with an oil temperature gauge; however, you can measure yours by “shooting” the approximate vertical and horizontal center of the oil pan with an infrared pyrometer (the best results for infrared pyrometers are achieved when the gun is held very close to the surface being measured, no more than two inches, and when used on surfaces that are non-reflective, flat, or ideally, satin black).

The consequences of running an engine with “cold” oil are an increase in sludge and varnish production within the oil as well as an inability for the oil to vaporize water that accumulates as a result of piston ring blow by, which itself is exacerbated by the aforementioned carbon formation.

Blow by is essentially combustion chamber gasses “leaking” past the piston rings into the crankcase, a small amount of which is normal, carrying with them some water that’s part of all diesel exhaust, along with unburned fuel and other combustion byproducts. Whether the blow by is normal or excessive, the water can only evaporate when the oil gets hot, over about 160 degrees F.

Sludge is a combination of water, carbon, and other contaminants. It impedes oil flow and, as the name implies, it’s greasy and often brown or tan in appearance; while varnish is a precipitate that is much harder, like, well, varnish. It adheres tenaciously to metal surfaces within the engine. Both of these contaminants are harmful to an engine, as they can starve vital components of lubricating oil.

The bottom line is to avoid chronically under loading your engine and, if you must do so, run it up to 75 percent load for 10-15 minutes out of every four hours. Doing so will raise the oil and combustion chamber temperature, and stem the sludge, varnish, and carbon tide. Perform oil analysis with each oil change (see PropTalk’s August Gearhead column for more on oil analysis). The former will increase oil and combustion chamber temperature to preferable levels, thereby reducing build ups, and the latter will alert you to contaminant-related issues caused by under-loading before they become critical.

About the Author: Former boatyard manager, technical writer, and lecturer Steve D’Antonio consults for boat owners and buyers, boat builders, and others in the industry. Visit

stevedmarine.com for his weekly technical columns.

What does it mean for your diesel engine?

I receive emails and questions during lectures from savvy boat owners on this subject again and again, and the volume of discussion on this issue is only exceeded by the confusion, concern, and lack of understanding it generates.

I read a boat review a few years back, in which the reviewer boasted that “…because the [subject vessel] achieved cruising speed while using only a fraction of the engine’s available power, the engine should therefore last forever.” It’s a concept that’s commonly misunderstood, and one that seems counterintuitive: the lighter the load on your engine, the greater the likelihood of developing problems. It’s true: when a diesel engine is chronically under-loaded, several phenomena occur that conspire to shorten the life of the engine, reduce efficiency, and increase the need for maintenance and possible repairs.

The environment inside a diesel engine combustion chamber is a hellish one indeed. The temperature can reach over 1000 degrees Fahrenheit while the pressure may be many times that of the atmosphere outside the engine. Interestingly, however, this is how a diesel engine is designed to operate most efficiently, at comparatively high temperature under relatively high load. The high pressure found within the combustion chamber represents the very philosophy of the diesel ignition process: compressing the air increases its temperature, which in turn enables it to ignite the subsequently injected fuel. While I’ll be the first to recognize that it’s not always possible for recreational vessels to be operated in this manner, ideally, it’s best to size engines so they are run most often at something over 50 percent load, and preferably closer to 75 percent. When operated in this manner, the temperature within the engine ensures greater efficiency and improved longevity. Contrary to popular belief, while they may have improved defenses against it, new, electronically controlled engines are not immune from issues created by chronic under-loading. Furthermore, chronic engine over-sizing exacerbates the issue.

What does it mean for your diesel engine?

I receive emails and questions during lectures from savvy boat owners on this subject again and again, and the volume of discussion on this issue is only exceeded by the confusion, concern, and lack of understanding it generates.

I read a boat review a few years back, in which the reviewer boasted that “…because the [subject vessel] achieved cruising speed while using only a fraction of the engine’s available power, the engine should therefore last forever.” It’s a concept that’s commonly misunderstood, and one that seems counterintuitive: the lighter the load on your engine, the greater the likelihood of developing problems. It’s true: when a diesel engine is chronically under-loaded, several phenomena occur that conspire to shorten the life of the engine, reduce efficiency, and increase the need for maintenance and possible repairs.

The environment inside a diesel engine combustion chamber is a hellish one indeed. The temperature can reach over 1000 degrees Fahrenheit while the pressure may be many times that of the atmosphere outside the engine. Interestingly, however, this is how a diesel engine is designed to operate most efficiently, at comparatively high temperature under relatively high load. The high pressure found within the combustion chamber represents the very philosophy of the diesel ignition process: compressing the air increases its temperature, which in turn enables it to ignite the subsequently injected fuel. While I’ll be the first to recognize that it’s not always possible for recreational vessels to be operated in this manner, ideally, it’s best to size engines so they are run most often at something over 50 percent load, and preferably closer to 75 percent. When operated in this manner, the temperature within the engine ensures greater efficiency and improved longevity. Contrary to popular belief, while they may have improved defenses against it, new, electronically controlled engines are not immune from issues created by chronic under-loading. Furthermore, chronic engine over-sizing exacerbates the issue.

When discussing proper operating temperature, it’s important to remember that there are several regions within the engine, all of which are almost certainly operating at different temperatures, under differing load conditions. For instance, when you start your engine and run it at idle or at low rpm, you may notice that the temperature gauge that measures coolant temperature doesn’t move very much. If it’s graduated in numbers as it should be, it’s unlikely that the needle passes 145 degrees F.

On the other hand, when a load is applied, if you are motoring hard to make port before a weather system descends upon you, for instance, the needle should hover around the engine’s maximum design operating and thermostat opening temperature, which for closed cooling system engines is typically, depending on the engine’s design, between 160 degrees F and 195 degrees F. In the light load condition, when the coolant temperature is low, it means the temperature of the combustion chamber is also lower than that which is optimal. This leads to the formation of excess soot or carbon, which is deposited on the piston rings, injectors, and valves, a scenario which reduces efficiency and may shorten the life of these components.

When discussing proper operating temperature, it’s important to remember that there are several regions within the engine, all of which are almost certainly operating at different temperatures, under differing load conditions. For instance, when you start your engine and run it at idle or at low rpm, you may notice that the temperature gauge that measures coolant temperature doesn’t move very much. If it’s graduated in numbers as it should be, it’s unlikely that the needle passes 145 degrees F.

On the other hand, when a load is applied, if you are motoring hard to make port before a weather system descends upon you, for instance, the needle should hover around the engine’s maximum design operating and thermostat opening temperature, which for closed cooling system engines is typically, depending on the engine’s design, between 160 degrees F and 195 degrees F. In the light load condition, when the coolant temperature is low, it means the temperature of the combustion chamber is also lower than that which is optimal. This leads to the formation of excess soot or carbon, which is deposited on the piston rings, injectors, and valves, a scenario which reduces efficiency and may shorten the life of these components.

Cylinder wall glazing, which exacerbates blow by, also occurs when an engine is chronically under loaded, especially early on in its life. Because they are often chronically under loaded in the critical break-in period, the first 50-100 hours, generators are notorious for suffering from this malady.

Even under moderate load, when the coolant reaches a normal operating temperature, unless the engine is equipped with an oil cooler thermostat, the oil temperature often remains cooler, too cool for optimum operation. This is a significant and often overlooked aspect of under-loading, and it isn’t mitigated by electronic, computer-controlled, diesel-fuel injection systems. Few engines are equipped with an oil temperature gauge; however, you can measure yours by “shooting” the approximate vertical and horizontal center of the oil pan with an infrared pyrometer (the best results for infrared pyrometers are achieved when the gun is held very close to the surface being measured, no more than two inches, and when used on surfaces that are non-reflective, flat, or ideally, satin black).

Cylinder wall glazing, which exacerbates blow by, also occurs when an engine is chronically under loaded, especially early on in its life. Because they are often chronically under loaded in the critical break-in period, the first 50-100 hours, generators are notorious for suffering from this malady.

Even under moderate load, when the coolant reaches a normal operating temperature, unless the engine is equipped with an oil cooler thermostat, the oil temperature often remains cooler, too cool for optimum operation. This is a significant and often overlooked aspect of under-loading, and it isn’t mitigated by electronic, computer-controlled, diesel-fuel injection systems. Few engines are equipped with an oil temperature gauge; however, you can measure yours by “shooting” the approximate vertical and horizontal center of the oil pan with an infrared pyrometer (the best results for infrared pyrometers are achieved when the gun is held very close to the surface being measured, no more than two inches, and when used on surfaces that are non-reflective, flat, or ideally, satin black).

The consequences of running an engine with “cold” oil are an increase in sludge and varnish production within the oil as well as an inability for the oil to vaporize water that accumulates as a result of piston ring blow by, which itself is exacerbated by the aforementioned carbon formation.

Blow by is essentially combustion chamber gasses “leaking” past the piston rings into the crankcase, a small amount of which is normal, carrying with them some water that’s part of all diesel exhaust, along with unburned fuel and other combustion byproducts. Whether the blow by is normal or excessive, the water can only evaporate when the oil gets hot, over about 160 degrees F.

The consequences of running an engine with “cold” oil are an increase in sludge and varnish production within the oil as well as an inability for the oil to vaporize water that accumulates as a result of piston ring blow by, which itself is exacerbated by the aforementioned carbon formation.

Blow by is essentially combustion chamber gasses “leaking” past the piston rings into the crankcase, a small amount of which is normal, carrying with them some water that’s part of all diesel exhaust, along with unburned fuel and other combustion byproducts. Whether the blow by is normal or excessive, the water can only evaporate when the oil gets hot, over about 160 degrees F.

Sludge is a combination of water, carbon, and other contaminants. It impedes oil flow and, as the name implies, it’s greasy and often brown or tan in appearance; while varnish is a precipitate that is much harder, like, well, varnish. It adheres tenaciously to metal surfaces within the engine. Both of these contaminants are harmful to an engine, as they can starve vital components of lubricating oil.

The bottom line is to avoid chronically under loading your engine and, if you must do so, run it up to 75 percent load for 10-15 minutes out of every four hours. Doing so will raise the oil and combustion chamber temperature, and stem the sludge, varnish, and carbon tide. Perform oil analysis with each oil change (see PropTalk’s August Gearhead column for more on oil analysis). The former will increase oil and combustion chamber temperature to preferable levels, thereby reducing build ups, and the latter will alert you to contaminant-related issues caused by under-loading before they become critical.

About the Author: Former boatyard manager, technical writer, and lecturer Steve D’Antonio consults for boat owners and buyers, boat builders, and others in the industry. Visit stevedmarine.com for his weekly technical columns.

Sludge is a combination of water, carbon, and other contaminants. It impedes oil flow and, as the name implies, it’s greasy and often brown or tan in appearance; while varnish is a precipitate that is much harder, like, well, varnish. It adheres tenaciously to metal surfaces within the engine. Both of these contaminants are harmful to an engine, as they can starve vital components of lubricating oil.

The bottom line is to avoid chronically under loading your engine and, if you must do so, run it up to 75 percent load for 10-15 minutes out of every four hours. Doing so will raise the oil and combustion chamber temperature, and stem the sludge, varnish, and carbon tide. Perform oil analysis with each oil change (see PropTalk’s August Gearhead column for more on oil analysis). The former will increase oil and combustion chamber temperature to preferable levels, thereby reducing build ups, and the latter will alert you to contaminant-related issues caused by under-loading before they become critical.

About the Author: Former boatyard manager, technical writer, and lecturer Steve D’Antonio consults for boat owners and buyers, boat builders, and others in the industry. Visit stevedmarine.com for his weekly technical columns.