February is right in the middle of the oystering season on the Chesapeake. It seems appropriate that our first two reports concern a boat type closely associated with Chesapeake oyster tonging: the Hoopers Island Draketail.

Tracy Johns of the Chesapeake Bay Maritime Museum (CBMM) in St. Michaels, MD, sends us the following report. “A 1934 Hoopers Island dovetail,

Dorothy Lee, has recently been added to CBMM’s floating fleet.

Dorothy Lee was generously donated by Susan Friedel of Trappe, MD, in honor of her late husband Jerry Friedel. Lovingly restored by Jerry,

Dorothy Lee was originally built by famed boat builder Bronza Parks at Bishops Head in Maryland’s Dorchester County. The boat was built for Theodore Woodland, also of Dorchester County, and joins the ranks of other Bronza Parks’ boats in CBMM’s collection, including the recently restored 1955 skipjack,

Rosie Parks, and

Martha, another 1934 dovetail.

‘Jerry would’ve just been so thrilled. This was always his wish,’ Susan Friedel said. ‘CBMM is such a wonderful place—the boat restoration work, the shipwright apprentice program—it’s all so nice. And it’s great to have the three Bronza Parks boats back together.’

[gallery columns="2" size="medium" link="file" ids="17654,17655"]

Dovetails, also called draketails, are named for their distinctive round sterns that rake or slope forward from the waterline to the deck; the stern tapers down to the water.

Dorothy Lee was built during a time when dovetails were used along the Chesapeake Bay for oyster tonging and trot lining for crabs.

Dorothy Lee measures 41.2 feet long and 8.2 feet in breadth, and was originally equipped with a 35-hp marine gasoline engine, which was larger than typical for this type of boat. ‘

Dorothy Lee’s long, narrow, light displacement hull would have made her a particularly fast workboat,’ said CBMM chief curator Pete Lesher. ‘Speed was the allure for watermen who bought Hoopers Island dovetails, with their distinctive racy round sterns that imitated racing motorboats, and the Navy’s torpedo boats from the turn of the century.”

We are indebted to Kathy Bergen Smith’s excellent article in the December issue of WorkBoat Magazine for the following report on a modern reincarnation of this traditional design:

Maritime Applied Physics Corp. (MAPC) in Baltimore delivered the first of what will be a new fleet of 10 water taxis for the city. The 55 foot by 12 foot nine inch by three foot one inch

Key’s Anthem is a 49-passenger vessel that pays homage to the past while embracing the future. The first boat,

Key’s Anthem, debuted during Fleet Week in October and marks a departure from the simple pontoon boats that comprise the current fleet. MAPC created an aluminum water taxi with a raised wheelhouse and round stern referencing the Hooper’s Island draketail. Unlike the pontoon boats, the new boats will load from amidships with wheelchair ramps. There is stowage for eight bicycles onboard. Seating is arranged on a continuous bench along the hull, including along the curved stern.

The flooring is Plastdek, a man-made, repairable material made to mimic a wooden deck. The new boats will evolve as the 10-boat order progresses.

Key’s Anthem is powered by twin Beta Marine diesel engines but future boats will be diesel-electric hybrids. The Beta engines are rated at just 38-hp each. The raised pilothouse features two captain’s chairs, one adjustable for young riders to climb into so they can get a look at the helm. Steering is provided by SeaStar Optimus electronic power steering. Navigational equipment is a Garmin GPSMAP 721. When it came to the exterior look of the boat, the MAPC team came up with a black hull with a boot stripe based on the Maryland flag.

Draketails are indeed handsome boats. As Larry Chowning observes in “Deadrise and Cross Planked,” his history of bay deadrises, “… the draketail stern did allow the boat to plane without squatting, but their appeal was mainly esthetic: Watermen just plain like a pretty stern.”

Alex Schlegel of Hartge Yacht Yard in Galesville, MD, sends us this report of work on a more modern classic. “In November and early December we were busy with the normal boatyard jobs of getting boats winterized, hauled, and otherwise prepared for winter. It looks to be a busy winter with several engines to install, a number of Awlgrip jobs and a lot of work on a 55-foot Trumpy. In early November, the 1950 Trumpy came back to our yard for the winter. Over many years we have repaired the foredeck, the cabin front, hardtop supports, shear planks, rub rails, fuel tanks, fuel lines, and under the aft cabin: frames and floors, blocking for struts and rudders, and double planking.

[gallery link="file" columns="2" size="medium" ids="17658,17659"]

Although this boat is 66 years old, she is still strong enough to haul with four belts in our travel lift; a testament to how well Trumpys were built. There were no cracking or popping sounds and no sagging. During the last haul out on a railway, the HYY carpenters, Ernie Stuermer and Peter Bell, noticed the turn of the bilge was not quite fair, which indicated broken frames. Sure enough, all frames we have uncovered so far have been broken, most behind a stringer. The planks’ seams opened a little bit near the cracks, allowing water to seep in and rust the bolts between the frames and stringer, which deteriorates the frames further. The frames probably cracked many years ago, for we see some frames repaired, and the present owner didn’t have it done. We’ll report more on this boat next month.”

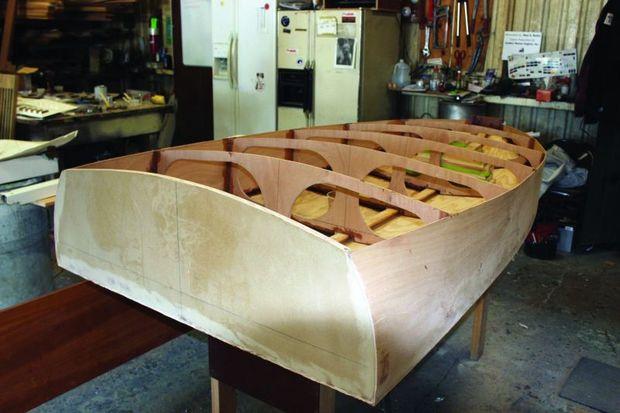

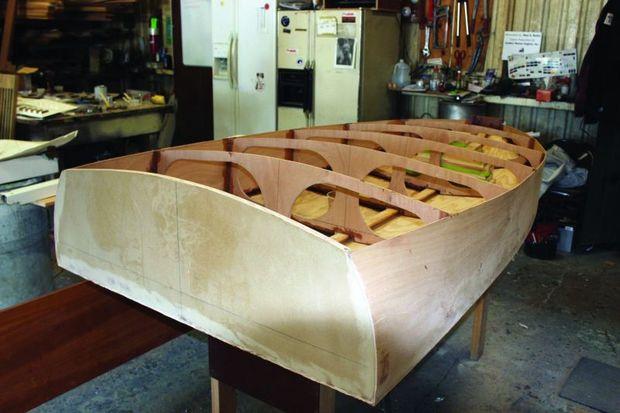

Joe Reid of Mast and Mallet in Edgewater, MD, reports a busy winter. “In the Mast and Mallet shop for winter hibernation are a wide variety of powerboat projects. Last month, we applied a triple ply bottom on a 1953 Chris-Craft 17-foot Sportsman and sheathed it with 10-ounce cloth and WEST epoxy. The new transom was installed with ribboned Sapele mahogany. Topside work will be next on the agenda. Also, a Seaway 24 outboard runabout has come inside for changes in helm and cockpit seating arrangements. And a ‘30-point checklist’ will take her to the spring readiness delivery. Back again this season is the 28-foot, 1972 Pacemaker that we rehabbed on the exterior last year. She is here for interior upgrades. In the construction department, the Cocktail class I started last winter will receive the top deck cover and interior.”

Patrick Callahan at Worton Creek Marina in Chestertown, MD

Patrick Callahan at Worton Creek Marina in Chestertown, MD, says: “The boat yard is very busy, and we’re scrambling to get estimates ready, figure out our winter scheduling, finish fall projects, put the marina to bed, haul boats, winterize boats, and everything else that needs to be done at the end of the season. We had our usual booth at the Annapolis Boat Show this year. In addition to the booth we partnered with Cummins Power and had our latest 31 Bertram on display (thanks to her owner who graciously let us have her for the show). Overall it was the best show we’ve had in years. Activity at the booth was strong and activity at the boat was unbelievable! Most people who walked by stopped, took pictures, asked questions and really admired the quality of work done on the boat. There are still a lot of people that know of and appreciate the 31-foot Bertram. I’m convinced that she was the queen of the show. I am very proud of our team here at Worton Creek for the outstanding work they performed in remanufacturing her. She is drop dead gorgeous with attention to detail that is breathtaking.”

Meg Roney from Mathews Brothers in Denton, MD

Meg Roney from Mathews Brothers in Denton, MD, brings us up to date from their busy shop: “We are very fortunate to be busy this winter! We recently pulled a 26-foot hull from the mold that will be the first Mathews Bros 26! Keep an eye out for Facebook posts and daily pictures for more information on this exciting opportunity. Our glass shop crew is also busy laying up a new Eastport 32. In addition to staying busy with new boats, we’re busy with engine maintenance on our storage boats as well as varnish and cosmetic jobs to get them ready to go for the approaching season. Down at the landing, the pilothouse was married to the hull (on the buy boat

Crow Bros. ll) back in October. Since then, we’ve installed the doors and windows as well as fabricated wire chases for the electrical systems. We’re now in the throes of installing the electrical and hydraulic systems.”

[gallery columns="2" link="file" size="medium" ids="17662,17663"]

by Capt. Rick Franke The flooring is Plastdek, a man-made, repairable material made to mimic a wooden deck. The new boats will evolve as the 10-boat order progresses. Key’s Anthem is powered by twin Beta Marine diesel engines but future boats will be diesel-electric hybrids. The Beta engines are rated at just 38-hp each. The raised pilothouse features two captain’s chairs, one adjustable for young riders to climb into so they can get a look at the helm. Steering is provided by SeaStar Optimus electronic power steering. Navigational equipment is a Garmin GPSMAP 721. When it came to the exterior look of the boat, the MAPC team came up with a black hull with a boot stripe based on the Maryland flag.

Draketails are indeed handsome boats. As Larry Chowning observes in “Deadrise and Cross Planked,” his history of bay deadrises, “… the draketail stern did allow the boat to plane without squatting, but their appeal was mainly esthetic: Watermen just plain like a pretty stern.”

Alex Schlegel of Hartge Yacht Yard in Galesville, MD, sends us this report of work on a more modern classic. “In November and early December we were busy with the normal boatyard jobs of getting boats winterized, hauled, and otherwise prepared for winter. It looks to be a busy winter with several engines to install, a number of Awlgrip jobs and a lot of work on a 55-foot Trumpy. In early November, the 1950 Trumpy came back to our yard for the winter. Over many years we have repaired the foredeck, the cabin front, hardtop supports, shear planks, rub rails, fuel tanks, fuel lines, and under the aft cabin: frames and floors, blocking for struts and rudders, and double planking.

[gallery link="file" columns="2" size="medium" ids="17658,17659"]

Although this boat is 66 years old, she is still strong enough to haul with four belts in our travel lift; a testament to how well Trumpys were built. There were no cracking or popping sounds and no sagging. During the last haul out on a railway, the HYY carpenters, Ernie Stuermer and Peter Bell, noticed the turn of the bilge was not quite fair, which indicated broken frames. Sure enough, all frames we have uncovered so far have been broken, most behind a stringer. The planks’ seams opened a little bit near the cracks, allowing water to seep in and rust the bolts between the frames and stringer, which deteriorates the frames further. The frames probably cracked many years ago, for we see some frames repaired, and the present owner didn’t have it done. We’ll report more on this boat next month.”

Joe Reid of Mast and Mallet in Edgewater, MD, reports a busy winter. “In the Mast and Mallet shop for winter hibernation are a wide variety of powerboat projects. Last month, we applied a triple ply bottom on a 1953 Chris-Craft 17-foot Sportsman and sheathed it with 10-ounce cloth and WEST epoxy. The new transom was installed with ribboned Sapele mahogany. Topside work will be next on the agenda. Also, a Seaway 24 outboard runabout has come inside for changes in helm and cockpit seating arrangements. And a ‘30-point checklist’ will take her to the spring readiness delivery. Back again this season is the 28-foot, 1972 Pacemaker that we rehabbed on the exterior last year. She is here for interior upgrades. In the construction department, the Cocktail class I started last winter will receive the top deck cover and interior.”

The flooring is Plastdek, a man-made, repairable material made to mimic a wooden deck. The new boats will evolve as the 10-boat order progresses. Key’s Anthem is powered by twin Beta Marine diesel engines but future boats will be diesel-electric hybrids. The Beta engines are rated at just 38-hp each. The raised pilothouse features two captain’s chairs, one adjustable for young riders to climb into so they can get a look at the helm. Steering is provided by SeaStar Optimus electronic power steering. Navigational equipment is a Garmin GPSMAP 721. When it came to the exterior look of the boat, the MAPC team came up with a black hull with a boot stripe based on the Maryland flag.

Draketails are indeed handsome boats. As Larry Chowning observes in “Deadrise and Cross Planked,” his history of bay deadrises, “… the draketail stern did allow the boat to plane without squatting, but their appeal was mainly esthetic: Watermen just plain like a pretty stern.”

Alex Schlegel of Hartge Yacht Yard in Galesville, MD, sends us this report of work on a more modern classic. “In November and early December we were busy with the normal boatyard jobs of getting boats winterized, hauled, and otherwise prepared for winter. It looks to be a busy winter with several engines to install, a number of Awlgrip jobs and a lot of work on a 55-foot Trumpy. In early November, the 1950 Trumpy came back to our yard for the winter. Over many years we have repaired the foredeck, the cabin front, hardtop supports, shear planks, rub rails, fuel tanks, fuel lines, and under the aft cabin: frames and floors, blocking for struts and rudders, and double planking.

[gallery link="file" columns="2" size="medium" ids="17658,17659"]

Although this boat is 66 years old, she is still strong enough to haul with four belts in our travel lift; a testament to how well Trumpys were built. There were no cracking or popping sounds and no sagging. During the last haul out on a railway, the HYY carpenters, Ernie Stuermer and Peter Bell, noticed the turn of the bilge was not quite fair, which indicated broken frames. Sure enough, all frames we have uncovered so far have been broken, most behind a stringer. The planks’ seams opened a little bit near the cracks, allowing water to seep in and rust the bolts between the frames and stringer, which deteriorates the frames further. The frames probably cracked many years ago, for we see some frames repaired, and the present owner didn’t have it done. We’ll report more on this boat next month.”

Joe Reid of Mast and Mallet in Edgewater, MD, reports a busy winter. “In the Mast and Mallet shop for winter hibernation are a wide variety of powerboat projects. Last month, we applied a triple ply bottom on a 1953 Chris-Craft 17-foot Sportsman and sheathed it with 10-ounce cloth and WEST epoxy. The new transom was installed with ribboned Sapele mahogany. Topside work will be next on the agenda. Also, a Seaway 24 outboard runabout has come inside for changes in helm and cockpit seating arrangements. And a ‘30-point checklist’ will take her to the spring readiness delivery. Back again this season is the 28-foot, 1972 Pacemaker that we rehabbed on the exterior last year. She is here for interior upgrades. In the construction department, the Cocktail class I started last winter will receive the top deck cover and interior.”

Patrick Callahan at Worton Creek Marina in Chestertown, MD, says: “The boat yard is very busy, and we’re scrambling to get estimates ready, figure out our winter scheduling, finish fall projects, put the marina to bed, haul boats, winterize boats, and everything else that needs to be done at the end of the season. We had our usual booth at the Annapolis Boat Show this year. In addition to the booth we partnered with Cummins Power and had our latest 31 Bertram on display (thanks to her owner who graciously let us have her for the show). Overall it was the best show we’ve had in years. Activity at the booth was strong and activity at the boat was unbelievable! Most people who walked by stopped, took pictures, asked questions and really admired the quality of work done on the boat. There are still a lot of people that know of and appreciate the 31-foot Bertram. I’m convinced that she was the queen of the show. I am very proud of our team here at Worton Creek for the outstanding work they performed in remanufacturing her. She is drop dead gorgeous with attention to detail that is breathtaking.”

Patrick Callahan at Worton Creek Marina in Chestertown, MD, says: “The boat yard is very busy, and we’re scrambling to get estimates ready, figure out our winter scheduling, finish fall projects, put the marina to bed, haul boats, winterize boats, and everything else that needs to be done at the end of the season. We had our usual booth at the Annapolis Boat Show this year. In addition to the booth we partnered with Cummins Power and had our latest 31 Bertram on display (thanks to her owner who graciously let us have her for the show). Overall it was the best show we’ve had in years. Activity at the booth was strong and activity at the boat was unbelievable! Most people who walked by stopped, took pictures, asked questions and really admired the quality of work done on the boat. There are still a lot of people that know of and appreciate the 31-foot Bertram. I’m convinced that she was the queen of the show. I am very proud of our team here at Worton Creek for the outstanding work they performed in remanufacturing her. She is drop dead gorgeous with attention to detail that is breathtaking.”

Meg Roney from Mathews Brothers in Denton, MD, brings us up to date from their busy shop: “We are very fortunate to be busy this winter! We recently pulled a 26-foot hull from the mold that will be the first Mathews Bros 26! Keep an eye out for Facebook posts and daily pictures for more information on this exciting opportunity. Our glass shop crew is also busy laying up a new Eastport 32. In addition to staying busy with new boats, we’re busy with engine maintenance on our storage boats as well as varnish and cosmetic jobs to get them ready to go for the approaching season. Down at the landing, the pilothouse was married to the hull (on the buy boat Crow Bros. ll) back in October. Since then, we’ve installed the doors and windows as well as fabricated wire chases for the electrical systems. We’re now in the throes of installing the electrical and hydraulic systems.”

[gallery columns="2" link="file" size="medium" ids="17662,17663"]

by Capt. Rick Franke

Meg Roney from Mathews Brothers in Denton, MD, brings us up to date from their busy shop: “We are very fortunate to be busy this winter! We recently pulled a 26-foot hull from the mold that will be the first Mathews Bros 26! Keep an eye out for Facebook posts and daily pictures for more information on this exciting opportunity. Our glass shop crew is also busy laying up a new Eastport 32. In addition to staying busy with new boats, we’re busy with engine maintenance on our storage boats as well as varnish and cosmetic jobs to get them ready to go for the approaching season. Down at the landing, the pilothouse was married to the hull (on the buy boat Crow Bros. ll) back in October. Since then, we’ve installed the doors and windows as well as fabricated wire chases for the electrical systems. We’re now in the throes of installing the electrical and hydraulic systems.”

[gallery columns="2" link="file" size="medium" ids="17662,17663"]

by Capt. Rick Franke