The boat shows are over, the ospreys and the snowbirds have gone south, the marina do-it-yourselfers are few and far between, and the rockfish season is about to end. It appears that Chesapeake country has “… just settled down for a long winter’s nap” (with apologies to Clement Moore). Well, not quite. The pace at local boat shops and marinas may be different from summer, but winterization, decommissioning, and postponed repairs will add up to a busy winter indeed.

Jake Glover of Ferry Point Marina in Trappe, MD, agrees. “The fall services and winterizations have already started. We have a number of fiberglass, paint, and gelcoat repairs on the books for this winter as well as two collision repairs. A couple of customers have already lined up some Awl-Grip paint work as well as a number of bottom jobs. These bottoms will be soda blasted, have blister repairs performed, and a complete Interlux Inter-Protect & Bottom Paint system applied. We also have a couple of Quicksilver re-manufactured 383 Mags on the way for a twin repower.”

Lauren DiStefano of Bluewater Yacht Yards in Hampton, VA, also reports a busy schedule. “Even the threat of a hurricane hasn’t slowed us down! Our service yard hauled roughly 53 boats in two days before the arrival of hurricane Joaquin. We have several teak jobs going on including a 2003 65-foot Mann custom: we are tearing out existing teak, installing new teak in the cockpit and mezzanine, and soda blasting and painting the bottom. A 2005 61-foot Viking yacht: we are removing all cockpit teak and installing new teak. A 2004 50-foot Viking sport cruiser: removing interior, aft bulk head, and engines for fuel tank replacement. A 2009 60-foot Viking yacht is in for a few upgrades before heading back to her home port in Texas: custom boot stripes, removing all rod holders, and building a custom fly bridge rocket launcher with 15 rod holders.”

Mike Moore of Cutts and Case in Oxford, MD

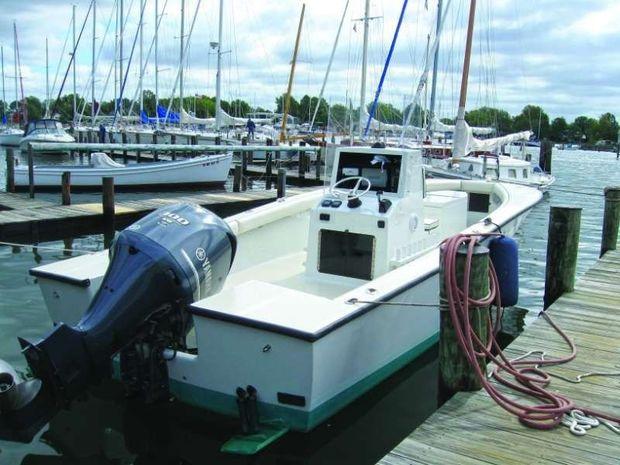

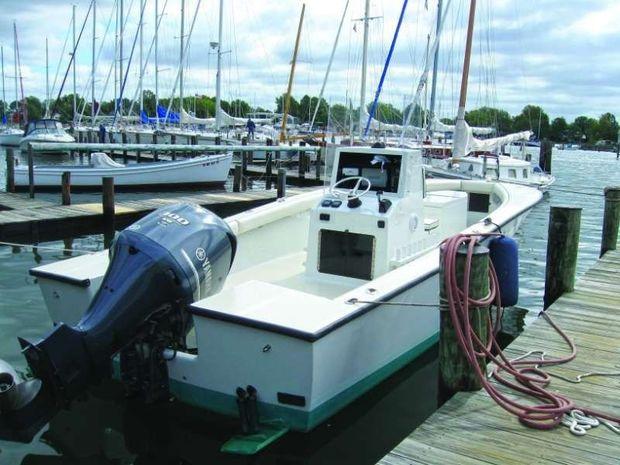

Mike Moore of Cutts and Case in Oxford, MD, sends us the following. “Cutts and Case is currently wrapping up a major project on an Edey and Duff Conch 27. This model has proven to be very popular among South Florida fishing guides. Work has included the replacement of the 200-gallon fuel tank and the deck as well. New cushions and electronics have been installed and Awl-Grip applied to the interior and console and non-skid on the wash boards.”

Joe Connor of Chesapeake Bay Maritime Museum (CBMM) in St. Michaels, MD

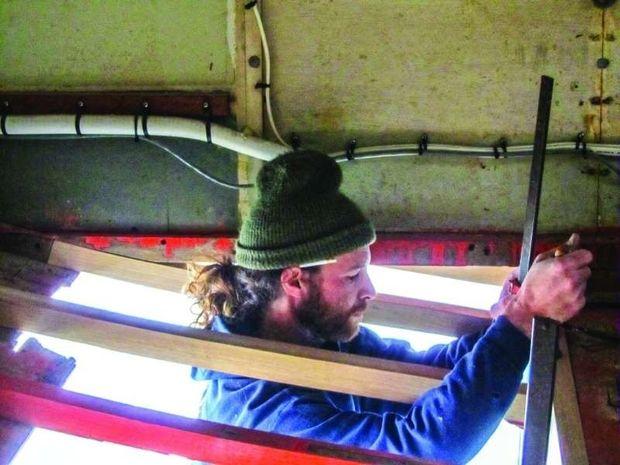

Joe Connor of Chesapeake Bay Maritime Museum (CBMM) in St. Michaels, MD, says, “CBMM’s tuck stern Pot Pie skiff is receiving some restoration work in the boatyard. Her hull has been flipped over, with deteriorating wood identified and removed. Shipwrights, apprentices, and volunteers are crafting new cypress bottom planking and white oak stringers, with sections of deadwood and a new horn timber to be crafted out of loblolly pine. The prop shaft will be re-drilled, and her 37-hp Westerbeke 4107 motor re-aligned once all work has been completed.

Waterman Lock Brando used this little skiff to catch crabs with a trotline and perhaps to tong for a few oysters. The boat is steered by a simple mechanism with a stick on the starboard, connected by ropes to the rudder in the stern. Chesapeake watermen like this kind of steering because they can steer with one hand and net crabs with the other hand. The Pot Pie skiff is named for the place it was built—a neighborhood called Pot Pie in the town of Wittman, MD. Some also refer to the boat type as a tuck stern skiff, because of the way the back of the boat is tucked up out of the water on each side. She was built in 1961 by George Jackson. Her length is 26 feet, with a beam of seven feet, 11 inches and a draft of one foot, 10 inches.”

David Evans Jr. of Evans Boats in Crisfield, MD

David Evans Jr. of Evans Boats in Crisfield, MD, expects a busy winter. “We have been wrapping up some finals on the 53-foot by 21-foot catamaran that we have been building from scratch for the last 10 months. Thankfully, the boat is almost complete and has found her way down the road and into the water! We are scheduled to deliver very soon, pending a few final USCG inspections. This boat will operate in the Boston Harbor by the Town of Winthrop as a Passenger Ferry rated for 78-plus passengers.

We have also been slowly but surely bringing a worn-down workboat back to life. This boat got a complete renovation and is leaving our shop refurbished and looking brand new! We will begin building our third boat for Disney Cruise Line in a few weeks, once the cat leaves the shop.”

Dave Hannam with Classic Watercraft Restoration in Annapolis

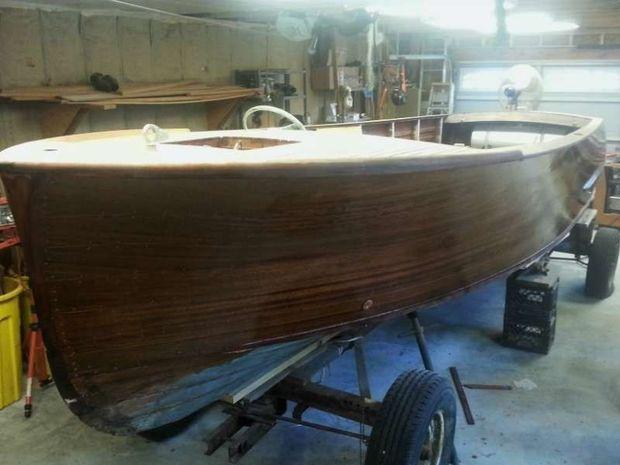

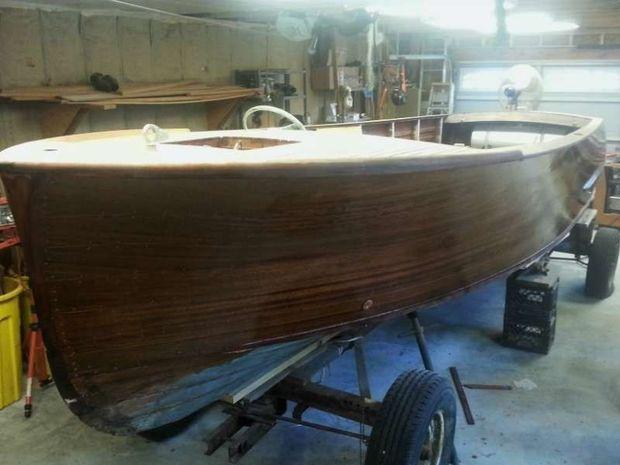

Dave Hannam with Classic Watercraft Restoration in Annapolis reports that projects are moving forward with the 1946 Chris-Craft U22 restoration, currently six weeks in. The Flagship Chevy 283 has been removed and is now in the engine shop. Hannam has started bench testing it to see what it’s going to take to revitalize the old girl. So far the plan is to add an electronic distributor and a new Rochester Carb, swapping out the original two-barrel carb with a Holley four-barrel and including a new intake. The mahogany hull was just topped off and received a total of 10 coats of varnish and is in the process of being polished. Re-seaming of the bottom is also under way, and plans for the new custom build interior are complete. Another Gar Wood Speedster 16-foot replica is being priced up for production, going to a long time classic boat owner to add to his collection, production scheduled to start early next year.

Meg Roney of Mathews Brothers Boatworks in Denton, MD

Meg Roney of Mathews Brothers Boatworks in Denton, MD, brings us up to date. “With Thanksgiving right around the corner, we would like to thank all of our customers for their business. We appreciate everyone who entrusts us with their boating needs. We had a successful Annapolis Boat Show in October with both new and familiar faces stopping to say hello. As always, the boat show was synonymous with the starting gun for our fall rush—we’ve been hauling boats out of the water ever since! A majority of these boats are our winter storage customers, so we’ve been busy winterizing and tucking these boats into our storage buildings. We will be addressing minor and major refits, as well as maintenance items, such as varnish, over the winter, so the boats will be ready for delivery in the spring—it will be here before we know it! We finished up the Eastport 32 Outboard Express in time for Eastport Yacht Company to display her both at the Annapolis and Ft. Lauderdale boat shows. We also just finished a Chris Craft repower with a 5.7L Volvo along with a new paint job, headliner replacements, and other minor refits.”

Tammy Eaton of Judge Yachts in Denton, MD, also reports a good show. “Judge Yachts wants to thank everyone who stopped by to see us at the Annapolis Boat Show. The Chesapeake 36 with Twin Outboards was a big hit, and we now have several new contracts that we are excited about starting. We recently delivered a 265 CC; we hope the new owners take the advice of their youngest son and name it Hot Buttered Lightning. The name makes absolutely no sense, but for some reason is rather catchy. We also have a couple of Chesapeake 27s in the works and look forward to a busy winter of building.”

Nancy Bray of Hartge Yacht Harbor on the West River in Galesville, MD

Nancy Bray of Hartge Yacht Harbor on the West River in Galesville, MD, reports on their latest project. “Hartge Yacht Harbor continues work on an aluminum boat here for a complete Awl-Grip paint job, both deck and hull sides. The process requires many steps, as most aluminum boat hulls are not fair. Beginning with blasting, the boat was coated with Hullguard, Awlfair, Highbuild, 545 primer, and topcoat. The painting of an aluminum boat poses some challenges, but the results are proving to be worth the effort.”

Jonathon Newton of Hartge Yacht Yard in Galesville, MD

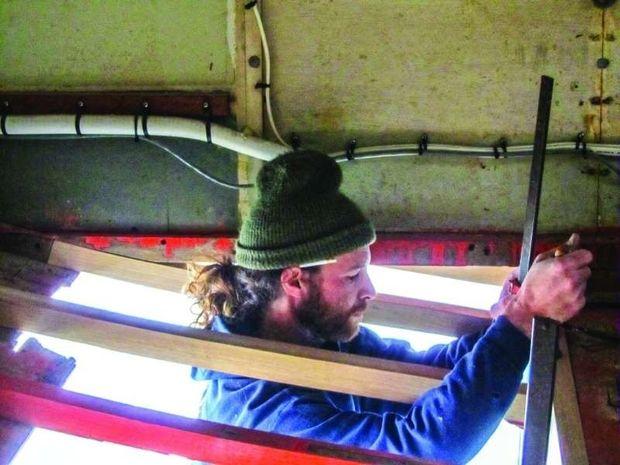

Jonathon Newton of Hartge Yacht Yard in Galesville, MD, shares the story of a major project with us. “From April thru mid-July our three extraordinary carpenters, Peter Bell, Ernie Stuermer, and Jake Samberg rebuilt a large portion of the bottom of a 1950s 55-foot Trumpy. Employed for the job were oak and ipe for floor timbers, rudder blocking, strut blocking, and shaft logs; oak for frames; cedar for inner planking; and mahogany for outer planking. In order to do the woodwork, they also removed and reinstalled the props, shafts, couplings, rudders, rudder boxes, steering system, and interior. After 60 years in the water, the wood had done all it could and had given up.

A major concern for a project like this is finding good material: bronze fasteners and big pieces of wood. Not finding good pieces of oak for the large floors and blocking, we looked for other suitable wood and to our surprise we found a great chunk of teak, but didn’t feel that was a place to put thousands of dollars of this especially valuable wood. For a much better price we found large timbers of ipe at J. Gibson McIlvain Co. It is very strong, durable, and so heavy it sinks like a rock. The white cedar supplied by Cedar Specialties in New Jersey was as fine as any I’ve seen. Bronze fasteners came from Chesapeake Fasteners, but we had to make some of the larger and longer bolts ourselves. We were able to reuse the original Monel strut bolts, a remarkable alloy that we have never seen deteriorate.

As you may remember, June was quite hot, causing the bottom planks to dry and the seams to open. We did the starboard side first and left the port side alone except for the floor timbers. When the starboard side was watertight, we launched her to swell up for a week or so and then rebuilt the port side. It’s a fine thing that there are people around who spend considerable resources to maintain these historic and fine yachts that were so beautifully built in Eastport.” Thanks for sharing Jonathon, and we couldn’t agree more.

More Projects:

[gallery link="file" size="medium" ids="11581,11582,11583,11584,11585,11586" orderby="rand"]

by Capt. Rick Franke Mike Moore of Cutts and Case in Oxford, MD, sends us the following. “Cutts and Case is currently wrapping up a major project on an Edey and Duff Conch 27. This model has proven to be very popular among South Florida fishing guides. Work has included the replacement of the 200-gallon fuel tank and the deck as well. New cushions and electronics have been installed and Awl-Grip applied to the interior and console and non-skid on the wash boards.”

Mike Moore of Cutts and Case in Oxford, MD, sends us the following. “Cutts and Case is currently wrapping up a major project on an Edey and Duff Conch 27. This model has proven to be very popular among South Florida fishing guides. Work has included the replacement of the 200-gallon fuel tank and the deck as well. New cushions and electronics have been installed and Awl-Grip applied to the interior and console and non-skid on the wash boards.”

Joe Connor of Chesapeake Bay Maritime Museum (CBMM) in St. Michaels, MD, says, “CBMM’s tuck stern Pot Pie skiff is receiving some restoration work in the boatyard. Her hull has been flipped over, with deteriorating wood identified and removed. Shipwrights, apprentices, and volunteers are crafting new cypress bottom planking and white oak stringers, with sections of deadwood and a new horn timber to be crafted out of loblolly pine. The prop shaft will be re-drilled, and her 37-hp Westerbeke 4107 motor re-aligned once all work has been completed.

Joe Connor of Chesapeake Bay Maritime Museum (CBMM) in St. Michaels, MD, says, “CBMM’s tuck stern Pot Pie skiff is receiving some restoration work in the boatyard. Her hull has been flipped over, with deteriorating wood identified and removed. Shipwrights, apprentices, and volunteers are crafting new cypress bottom planking and white oak stringers, with sections of deadwood and a new horn timber to be crafted out of loblolly pine. The prop shaft will be re-drilled, and her 37-hp Westerbeke 4107 motor re-aligned once all work has been completed.

Waterman Lock Brando used this little skiff to catch crabs with a trotline and perhaps to tong for a few oysters. The boat is steered by a simple mechanism with a stick on the starboard, connected by ropes to the rudder in the stern. Chesapeake watermen like this kind of steering because they can steer with one hand and net crabs with the other hand. The Pot Pie skiff is named for the place it was built—a neighborhood called Pot Pie in the town of Wittman, MD. Some also refer to the boat type as a tuck stern skiff, because of the way the back of the boat is tucked up out of the water on each side. She was built in 1961 by George Jackson. Her length is 26 feet, with a beam of seven feet, 11 inches and a draft of one foot, 10 inches.”

Waterman Lock Brando used this little skiff to catch crabs with a trotline and perhaps to tong for a few oysters. The boat is steered by a simple mechanism with a stick on the starboard, connected by ropes to the rudder in the stern. Chesapeake watermen like this kind of steering because they can steer with one hand and net crabs with the other hand. The Pot Pie skiff is named for the place it was built—a neighborhood called Pot Pie in the town of Wittman, MD. Some also refer to the boat type as a tuck stern skiff, because of the way the back of the boat is tucked up out of the water on each side. She was built in 1961 by George Jackson. Her length is 26 feet, with a beam of seven feet, 11 inches and a draft of one foot, 10 inches.”

David Evans Jr. of Evans Boats in Crisfield, MD, expects a busy winter. “We have been wrapping up some finals on the 53-foot by 21-foot catamaran that we have been building from scratch for the last 10 months. Thankfully, the boat is almost complete and has found her way down the road and into the water! We are scheduled to deliver very soon, pending a few final USCG inspections. This boat will operate in the Boston Harbor by the Town of Winthrop as a Passenger Ferry rated for 78-plus passengers.

We have also been slowly but surely bringing a worn-down workboat back to life. This boat got a complete renovation and is leaving our shop refurbished and looking brand new! We will begin building our third boat for Disney Cruise Line in a few weeks, once the cat leaves the shop.”

David Evans Jr. of Evans Boats in Crisfield, MD, expects a busy winter. “We have been wrapping up some finals on the 53-foot by 21-foot catamaran that we have been building from scratch for the last 10 months. Thankfully, the boat is almost complete and has found her way down the road and into the water! We are scheduled to deliver very soon, pending a few final USCG inspections. This boat will operate in the Boston Harbor by the Town of Winthrop as a Passenger Ferry rated for 78-plus passengers.

We have also been slowly but surely bringing a worn-down workboat back to life. This boat got a complete renovation and is leaving our shop refurbished and looking brand new! We will begin building our third boat for Disney Cruise Line in a few weeks, once the cat leaves the shop.”

Dave Hannam with Classic Watercraft Restoration in Annapolis reports that projects are moving forward with the 1946 Chris-Craft U22 restoration, currently six weeks in. The Flagship Chevy 283 has been removed and is now in the engine shop. Hannam has started bench testing it to see what it’s going to take to revitalize the old girl. So far the plan is to add an electronic distributor and a new Rochester Carb, swapping out the original two-barrel carb with a Holley four-barrel and including a new intake. The mahogany hull was just topped off and received a total of 10 coats of varnish and is in the process of being polished. Re-seaming of the bottom is also under way, and plans for the new custom build interior are complete. Another Gar Wood Speedster 16-foot replica is being priced up for production, going to a long time classic boat owner to add to his collection, production scheduled to start early next year.

Dave Hannam with Classic Watercraft Restoration in Annapolis reports that projects are moving forward with the 1946 Chris-Craft U22 restoration, currently six weeks in. The Flagship Chevy 283 has been removed and is now in the engine shop. Hannam has started bench testing it to see what it’s going to take to revitalize the old girl. So far the plan is to add an electronic distributor and a new Rochester Carb, swapping out the original two-barrel carb with a Holley four-barrel and including a new intake. The mahogany hull was just topped off and received a total of 10 coats of varnish and is in the process of being polished. Re-seaming of the bottom is also under way, and plans for the new custom build interior are complete. Another Gar Wood Speedster 16-foot replica is being priced up for production, going to a long time classic boat owner to add to his collection, production scheduled to start early next year.

Meg Roney of Mathews Brothers Boatworks in Denton, MD, brings us up to date. “With Thanksgiving right around the corner, we would like to thank all of our customers for their business. We appreciate everyone who entrusts us with their boating needs. We had a successful Annapolis Boat Show in October with both new and familiar faces stopping to say hello. As always, the boat show was synonymous with the starting gun for our fall rush—we’ve been hauling boats out of the water ever since! A majority of these boats are our winter storage customers, so we’ve been busy winterizing and tucking these boats into our storage buildings. We will be addressing minor and major refits, as well as maintenance items, such as varnish, over the winter, so the boats will be ready for delivery in the spring—it will be here before we know it! We finished up the Eastport 32 Outboard Express in time for Eastport Yacht Company to display her both at the Annapolis and Ft. Lauderdale boat shows. We also just finished a Chris Craft repower with a 5.7L Volvo along with a new paint job, headliner replacements, and other minor refits.”

Tammy Eaton of Judge Yachts in Denton, MD, also reports a good show. “Judge Yachts wants to thank everyone who stopped by to see us at the Annapolis Boat Show. The Chesapeake 36 with Twin Outboards was a big hit, and we now have several new contracts that we are excited about starting. We recently delivered a 265 CC; we hope the new owners take the advice of their youngest son and name it Hot Buttered Lightning. The name makes absolutely no sense, but for some reason is rather catchy. We also have a couple of Chesapeake 27s in the works and look forward to a busy winter of building.”

Meg Roney of Mathews Brothers Boatworks in Denton, MD, brings us up to date. “With Thanksgiving right around the corner, we would like to thank all of our customers for their business. We appreciate everyone who entrusts us with their boating needs. We had a successful Annapolis Boat Show in October with both new and familiar faces stopping to say hello. As always, the boat show was synonymous with the starting gun for our fall rush—we’ve been hauling boats out of the water ever since! A majority of these boats are our winter storage customers, so we’ve been busy winterizing and tucking these boats into our storage buildings. We will be addressing minor and major refits, as well as maintenance items, such as varnish, over the winter, so the boats will be ready for delivery in the spring—it will be here before we know it! We finished up the Eastport 32 Outboard Express in time for Eastport Yacht Company to display her both at the Annapolis and Ft. Lauderdale boat shows. We also just finished a Chris Craft repower with a 5.7L Volvo along with a new paint job, headliner replacements, and other minor refits.”

Tammy Eaton of Judge Yachts in Denton, MD, also reports a good show. “Judge Yachts wants to thank everyone who stopped by to see us at the Annapolis Boat Show. The Chesapeake 36 with Twin Outboards was a big hit, and we now have several new contracts that we are excited about starting. We recently delivered a 265 CC; we hope the new owners take the advice of their youngest son and name it Hot Buttered Lightning. The name makes absolutely no sense, but for some reason is rather catchy. We also have a couple of Chesapeake 27s in the works and look forward to a busy winter of building.”

Nancy Bray of Hartge Yacht Harbor on the West River in Galesville, MD, reports on their latest project. “Hartge Yacht Harbor continues work on an aluminum boat here for a complete Awl-Grip paint job, both deck and hull sides. The process requires many steps, as most aluminum boat hulls are not fair. Beginning with blasting, the boat was coated with Hullguard, Awlfair, Highbuild, 545 primer, and topcoat. The painting of an aluminum boat poses some challenges, but the results are proving to be worth the effort.”

Nancy Bray of Hartge Yacht Harbor on the West River in Galesville, MD, reports on their latest project. “Hartge Yacht Harbor continues work on an aluminum boat here for a complete Awl-Grip paint job, both deck and hull sides. The process requires many steps, as most aluminum boat hulls are not fair. Beginning with blasting, the boat was coated with Hullguard, Awlfair, Highbuild, 545 primer, and topcoat. The painting of an aluminum boat poses some challenges, but the results are proving to be worth the effort.”

Jonathon Newton of Hartge Yacht Yard in Galesville, MD, shares the story of a major project with us. “From April thru mid-July our three extraordinary carpenters, Peter Bell, Ernie Stuermer, and Jake Samberg rebuilt a large portion of the bottom of a 1950s 55-foot Trumpy. Employed for the job were oak and ipe for floor timbers, rudder blocking, strut blocking, and shaft logs; oak for frames; cedar for inner planking; and mahogany for outer planking. In order to do the woodwork, they also removed and reinstalled the props, shafts, couplings, rudders, rudder boxes, steering system, and interior. After 60 years in the water, the wood had done all it could and had given up.

Jonathon Newton of Hartge Yacht Yard in Galesville, MD, shares the story of a major project with us. “From April thru mid-July our three extraordinary carpenters, Peter Bell, Ernie Stuermer, and Jake Samberg rebuilt a large portion of the bottom of a 1950s 55-foot Trumpy. Employed for the job were oak and ipe for floor timbers, rudder blocking, strut blocking, and shaft logs; oak for frames; cedar for inner planking; and mahogany for outer planking. In order to do the woodwork, they also removed and reinstalled the props, shafts, couplings, rudders, rudder boxes, steering system, and interior. After 60 years in the water, the wood had done all it could and had given up.

A major concern for a project like this is finding good material: bronze fasteners and big pieces of wood. Not finding good pieces of oak for the large floors and blocking, we looked for other suitable wood and to our surprise we found a great chunk of teak, but didn’t feel that was a place to put thousands of dollars of this especially valuable wood. For a much better price we found large timbers of ipe at J. Gibson McIlvain Co. It is very strong, durable, and so heavy it sinks like a rock. The white cedar supplied by Cedar Specialties in New Jersey was as fine as any I’ve seen. Bronze fasteners came from Chesapeake Fasteners, but we had to make some of the larger and longer bolts ourselves. We were able to reuse the original Monel strut bolts, a remarkable alloy that we have never seen deteriorate.

As you may remember, June was quite hot, causing the bottom planks to dry and the seams to open. We did the starboard side first and left the port side alone except for the floor timbers. When the starboard side was watertight, we launched her to swell up for a week or so and then rebuilt the port side. It’s a fine thing that there are people around who spend considerable resources to maintain these historic and fine yachts that were so beautifully built in Eastport.” Thanks for sharing Jonathon, and we couldn’t agree more.

More Projects:

[gallery link="file" size="medium" ids="11581,11582,11583,11584,11585,11586" orderby="rand"]

by Capt. Rick Franke

A major concern for a project like this is finding good material: bronze fasteners and big pieces of wood. Not finding good pieces of oak for the large floors and blocking, we looked for other suitable wood and to our surprise we found a great chunk of teak, but didn’t feel that was a place to put thousands of dollars of this especially valuable wood. For a much better price we found large timbers of ipe at J. Gibson McIlvain Co. It is very strong, durable, and so heavy it sinks like a rock. The white cedar supplied by Cedar Specialties in New Jersey was as fine as any I’ve seen. Bronze fasteners came from Chesapeake Fasteners, but we had to make some of the larger and longer bolts ourselves. We were able to reuse the original Monel strut bolts, a remarkable alloy that we have never seen deteriorate.

As you may remember, June was quite hot, causing the bottom planks to dry and the seams to open. We did the starboard side first and left the port side alone except for the floor timbers. When the starboard side was watertight, we launched her to swell up for a week or so and then rebuilt the port side. It’s a fine thing that there are people around who spend considerable resources to maintain these historic and fine yachts that were so beautifully built in Eastport.” Thanks for sharing Jonathon, and we couldn’t agree more.

More Projects:

[gallery link="file" size="medium" ids="11581,11582,11583,11584,11585,11586" orderby="rand"]

by Capt. Rick Franke