As spring turns to summer and the pace on the water increases, area boatshops continue to be busy. Many have hiring signs on their websites. All the news media recession talk is concerning, but the general attitude seems to be guarded optimism and a wait and see attitude to see what really develops.

Any time a group of boaters get together to talk about their favorite powerboats, very shortly the subject of Bertram 31s usually crops up. They seem to be everybody’s (including your author’s) favorite boat. The following story is excerpted from a longer article about Jim Swagler, proprietor of Jim’s Marine in Ocean City, MD, and was supplied by frequent contributor Bill Griffin from the Awlgrip blog (awlgrip.com).

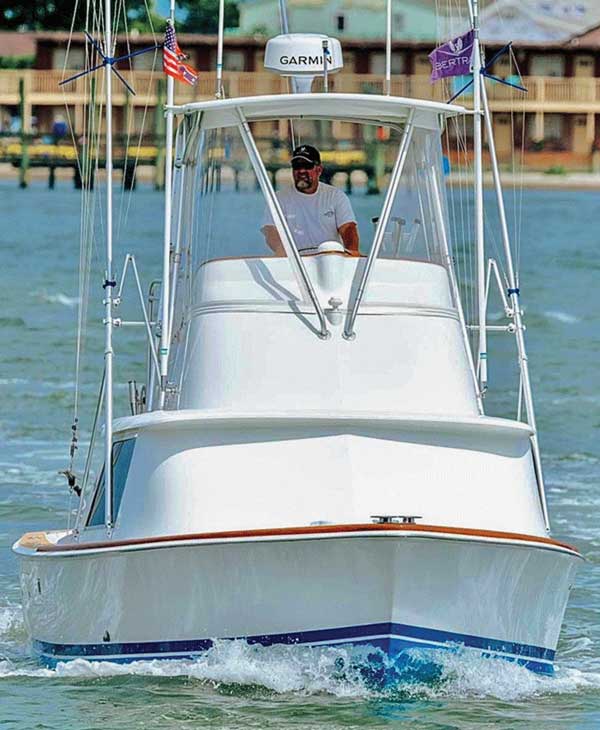

Bertram is a brand name that already carries a cult status for style and craftsmanship and Jim Swagler’s classic 1977 flybridge cruiser model is a shining example of the brand at their best. Jim spent four years painstakingly restoring it to show off all its sleek beauty, inside and out. For Jim, this has been the ultimate pride and passion project. The 52-year-old has spent his whole life on and around boats, fishing, repairing, maintaining and enjoying that feeling of being on the water.

We’ll let Jim tell the story.

“I was brought up on Bertrams,” he says. “That name has such a status among everyone who knows about boats. My dad had a couple when I was young and I remember fishing with him at the age of 12 or 13. Then, when he ran a charter yacht business here in Ocean City, I started to clean the boat up for him in the evenings.”

Fast forward three decades, Jim is now running his own maintenance business in his hometown, Ocean City, MD. Jim›s Marine has been proudly serving the sport and recreational boating community for more than 32 years and is an industry leader in quality and efficiency. Having previously offered all services from mechanical work to electrical rewires, Jim decided to zero in on his passion of refurbishments, repairs, and customization around 16 years ago. In the spring of 2016, he received a job out of the blue that eventually led to making his dreams come true.

“One day a guy called me to work on his boat. I didn’t know him from Adam, but I did the job and got him back in the water. On the last day, I was up there and we were chatting about fishing and he told me ‘I have a 31. It’s for sale’. I go ‘Oh yeah? What exactly do you have?’”

It was a 1977 Bertram 31, a flybridge cruiser.

“It was up in Annapolis, more than 100 miles up-river. It took me a long while to go look at it because it wasn’t in my price range, but I finally went up to take a look. Once I’d seen it and lifted up the hatches, I knew I was going to make an offer.”

Getting his dream boat was one thing. Getting it how he wanted would take many years of planning, sweat, and paint. He knew he could count on AkzoNobel’s portfolio of yacht brands to bring his dream to life.

“My dad and I always used Awlgrip and Interlux on our boats. AkzoNobel is the one that never lets you down.” says Jim. Facing a total refurbishment job, he started planning.

Calling on his years of experience in the industry, Jim worked through the refit from top to bottom, carefully selecting the right products for each job.

The entire boat (hull, superstructure, and inside of the cabin) was primed with Awlgrip 545 Epoxy Primer and then painted with Awlcraft 2000 Off-White.

The bottom was media blasted back to gelcoat. The underwater running gear, thru-hulls, and drains were all flushed and faired in with the use of Awlgrip Awlfair fairing compound.

“Then I applied four coats of Interlux InterProtect 2000E epoxy barrier system on the bottom and sanded it all down. Just around the waterline, transom, and from the bow stem back to the front of the cabin windshield was done in Interlux Micron CSC blue antifouling bottom paint,” Jim said.

“The rest of the running surface back to the bottom edge of the transom was done with Interlux VC Offshore blue antifouling bottom paint. Four coats were applied and left to dry, and then we wet sanded it out to 600 grit and burnished it to a slick shine. It’s real slick and smooth, I try to get the best efficiency I can between fuel and speed. On the non-running parts, I used Micron Extra SPC antifouling paint.”

“Everything is customized on the interior,” says Jim. “Originally, the Bertram was all done in dark brown Formica and that really drew everything down. So, I made custom cabinets, molded them in, and applied Awlgrip Quick Build as the primer.

Now, after four years of work, Jim is happy to call the project complete and is taking time to enjoy the Swagger, an appropriate name for this boat and a play on Jim’s last name, Swagler.

To read the full story, visit awlgrip.com/north-america/news/jim-swagler.

Next, we hear from Andy Dize at Roudebush Yacht and Engine Works in Dundalk, MD. “The weather as well as the workload have improved for RY&EW. Along with our normal spring routine of boat repair and bottom painting, we are currently in the final welding of hull number one and fit-up of hull number two for two new 28-foot aluminum dive support boats for Marine Solutions, Inc. We are also in the planning stages to build a fiberglass Wave Rover 650 for a private client. The dive support boat project is a collaboration of a number of Bay Area companies. Chesapeake Marine Design of Severna Park developed the hull form. The aluminum pieces were waterjet cut by Extreme Machining of Newark, DE. Welding support is being provided by Miller Marine Fabrication in North East, MD, and On Point Welding of Edgemere. Completion of the dive boats is scheduled for late June.”

“The construction of the new Wave Rover 650 will be Coosa-cored fiberglass versus the prototype which was marine plywood and fiberglass” Andy continued. “We are looking to start the Wave Rover construction mid-summer. Additional work on tap includes two 40-foot boat re-engining projects: one gas, one diesel. RY&EW is a full-service yard able to lift and repair boats up to 44 feet. Please reach out to Andy to discuss your future boat maintenance needs.”

Joe Reid of Mast and Mallet in Edgewater, MD, has been building a line of unique cruising boats for more than 30 years. The boats range from 23 to 44 feet, and all carry the name Thomas Point. The very first Thomas Point 30 is currently in the yard for painting. Also in the yard for winter storage and bottom paint are Sawdust, a Thomas Point 43, and a Thomas Point 44 named Impromptu. The boats have a timeless Chesapeake inspired design and sport a fit and finish that belies their age.

Joe explained why his boats still look so good.

“The hulls are cold-molded to one-inch thick, with two layers of cedar laid fore and aft and glued with Gougeon Bros. West Epoxy. Planks are glued between layers to three-fourths inches by three-inch frames. The exterior of the hulls are saturated with epoxy and sheathed with two layers of 10 oz. fiberglass cloth for extra strength and resistance to abrasion. All interior surfaces are coated with an epoxy barrier coating for an especially clean, finished appearance, and all other exterior areas are sheathed in epoxy/fiberglass. This method of construction results in a very strong, lightweight hull while eliminating or reducing the maintenance problems normally associated with traditional wood construction.”

Rob Hardy of Composite Yacht in Trappe, MD, reports a busy shop this spring. They are still in the spring commissioning rush and completing winter projects. One is a CY46 being custom built for St. Mary’s College of Maryland as a research vessel to support their education programs. One project created quite a stir when a small racing three point hydroplane appeared in the paint shop. “We are not going into the race boat business,” Rob laughed. “I was repainting it for a friend.”

Another interesting project nearing completion is the restoration and updating of a Palm Beach 37 that was once owned by movie star Burt Reynolds.

A last and final reminder. Please make arrangements to recycle the shrinkwrap that comes off your boat. If you have not already done so go to the Marine Trades Association website at mtam.org to learn how to do it.

By Capt. Rick Franke